全不锈钢结构可实现稳健而精确的运动控制

交叉滚子轴承确保任何轴上的角度偏差均小于 100 µrad

可用于 XZ 和 XYZ 配置

也可提供左手版本

预装的交叉滚子轴承提供可重复的零粘滑线性运动、可忽略不计的侧向游隙。滚轮条使圆柱形滚轮保持交替倾斜 90°,以确保与硬化和接地路线的恒定线性接触。

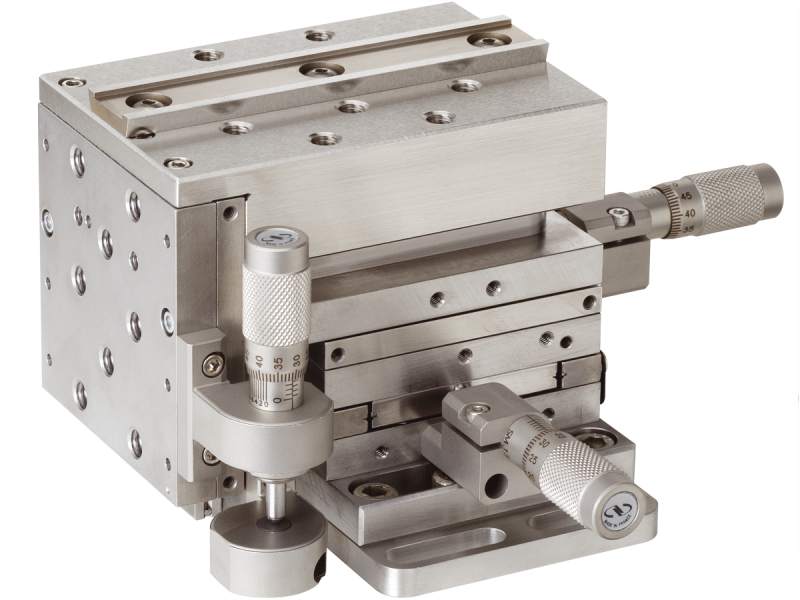

561 和 562 系列 ULTRAlign™ 精密光纤对准位移台采用不锈钢结构,用于光纤的精确对准和长期稳定性。通过具有较好性能的热匹配、硬化钢、交叉滚子轴承,精密制造的轴承系统具有在任何轴上 <100 µrad 角度偏差的线性行程。我们用六轴干涉测量仪测试每个位移台以确保性能。562 系列位移台的坚固设计使其适合重复、高使用率的光纤制造和研究应用。这些位移台由于其较高的质量而具有比铝位移台更大的抗热性,同时较大直径的轴承可增加位移台的刚度。左侧和右侧两个位移台都可用于人体工程学促动器放置。

顶部安装的导轨确保光纤系统和设备支架的精确和安全连接,用于通过多种光纤对准配件进行对准。倾斜平台可以用于光纤到设备的两轴翻转/倾斜对准。还可以添加测角仪以提供围绕光纤轴的旋转控制。可实现高达六个自由度,这些高性能 ULTRAlign 位移台提供了光纤对准解决方案。

通过使用 561-ADPT 适配器,ULTRAlign 561D-XYZ 和 561D-YZ 位移台的光学高度可以匹配 562F-XYZ 的光学高度。这将允许您在一个系统中使用两个系列的位移台。

562 系列位移台每个轴都配有零干扰锁紧机制,以在接合或脱离时保持亚微米级灵敏度的对准。

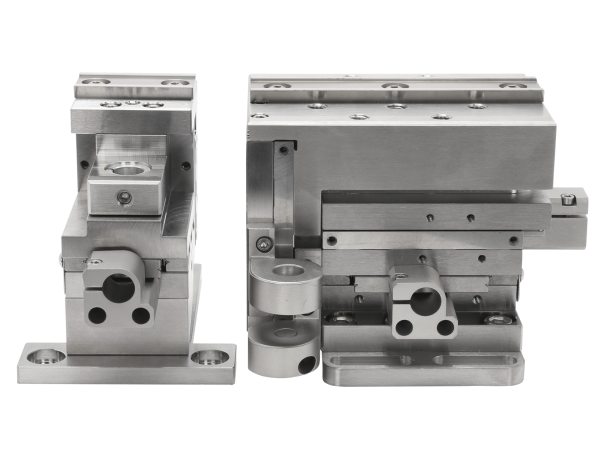

ULTRAlign™ XYZ stages come in mirror-image right and left-hand versions. This permits all micrometers to be located on the same side, so there's never a need to reach over your work to make adjustments on the opposite side. It also means you have more flexibility in how you lay out your experiment on the table. All adjustments can be made with the hand resting on the table for maximum comfort, added stability, and increased sensitivity.

全不锈钢结构

562 系列位移台具有专门设计的促动器安装块,可在任何轴上随时快速轻松地更换促动器。562 系列位移台在销售时不带促动器,可全面选择手动或电动促动器。

An easy-to-use dovetail mounting rail on the top surface of ULTRAlign stages provides a single, common reference surface for precise and secure attachment of fiber systems and device holders for alignment from the wide selection of fiber alignment accessories. We offer a wide range of accessories specifically designed for use with the 561 and 562 Series Fiber Alignment Stages, including fiber holders and positioners, GRIN Lens and objective mounts, a variety of platforms, and a vacuum waveguide mount with eight vacuum ports. Shown is

全不锈钢结构

全不锈钢结构

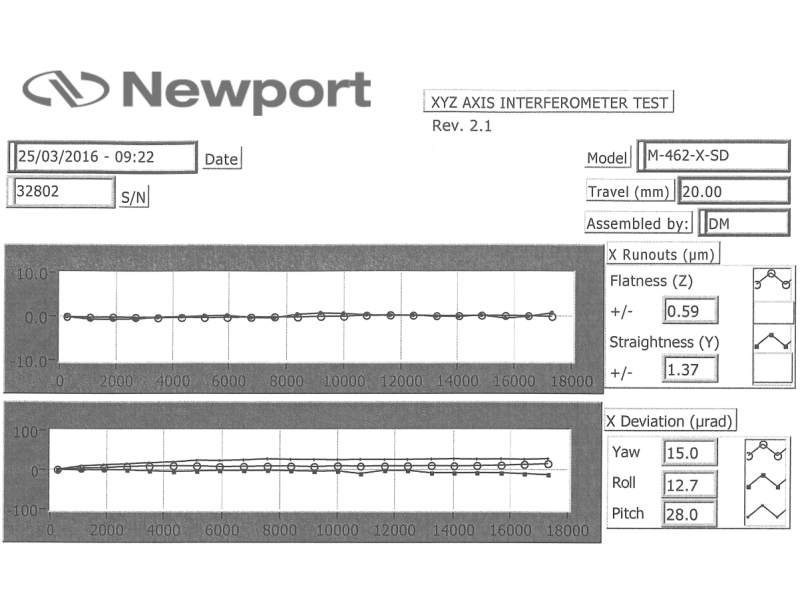

Each ULTRAlign Stainless Steel Crossed-Roller Translation Stage is tested individually to ensure it meets the <100 µrad angular deviation requirement. We don't just say it, we guarantee it. The actual test results are included with each stage.

全不锈钢结构

Left:

Right: 561D-XYZ, 561-TILT,

全不锈钢结构

Left: 561D-XYZ-LH,

Right: 561D-YZ,

全不锈钢结构

Left: 561D-YZ,

Right: 561D-XYZ,

全不锈钢结构

Left: 561D-YZ,

Right: 561D-XYZ, 561-TILT,

全不锈钢结构

Left: 561D-XYZ-LH,

Middle: 561D-YZ,

Right: 561D-XYZ, 561-TILT,

全不锈钢结构

Left: 561D-XYZ-LH,

Middle:

Right: 561D-XYZ, 561-TILT,