Design Features

Ideal for use with a wide variety of commercial femtosecond lasers

Optics selections for compatibility with 1030 nm, 1064 nm, 515 nm, or 532 nm wavelengths

Water- and air-cooling features for maximum stability and consistent performance over time

Produces precise features with the greatest

laser-processing precision available—even including features larger than

the scanner’s field of view

User-friendly features simplify integration into a machine, system, or subsystem

Assist gas pressure up to 200 psig for improved processing of high-aspect ratio features

The AGV5D five-axis laser micromachining precession scanner is

the fastest, most flexible and exacting solution for generating precise

holes, contoured slots and other geometries with fully defined cross

sections. It enables you to take control of your entire precision

micromachining process, from the laser, to the scanning head, to the

positioning of the workpiece.

Key Applications

Medical device manufacturing

Microelectronics processing

Automotive component manufacturing

Laser micromachining systems

Beam Manipulation in 5 Degrees of Freedom

Aerotech’s AGV5D five-axis laser micromachining precession scanner manipulates a laser beam in five degrees of freedom (DOF):

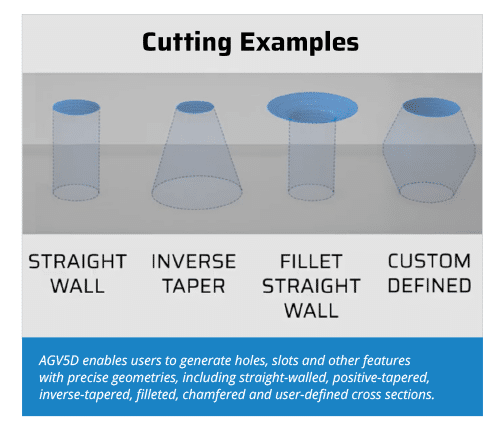

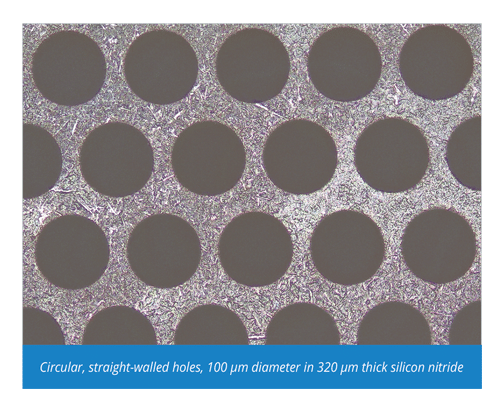

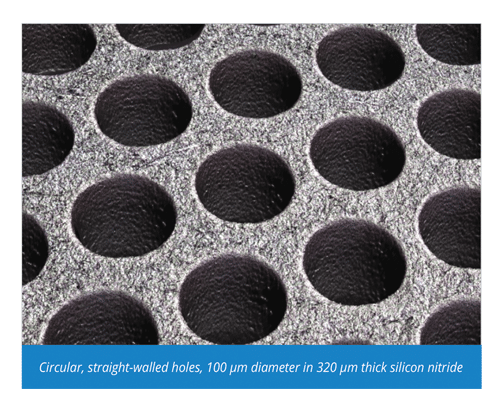

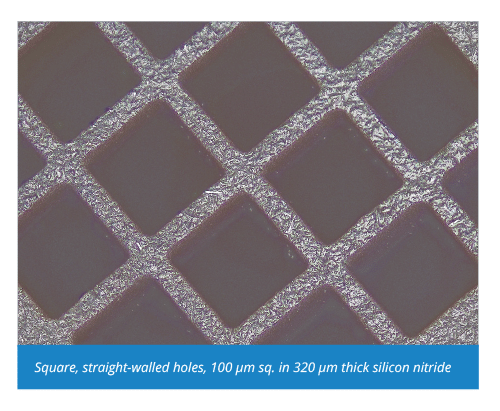

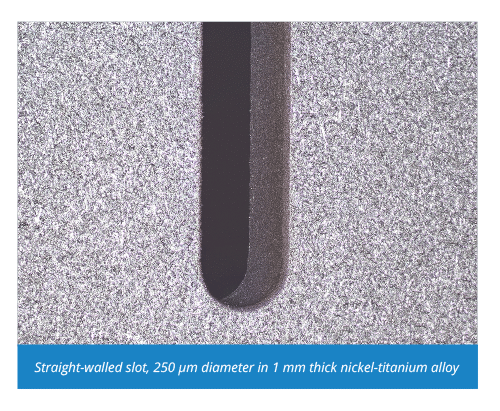

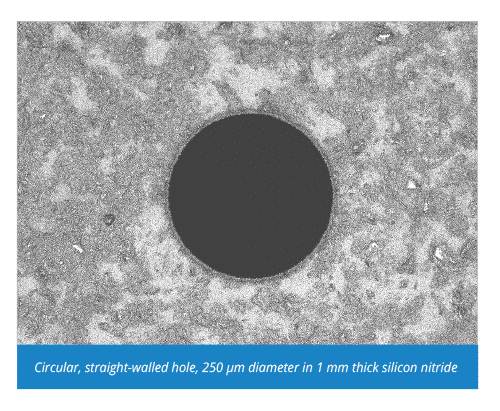

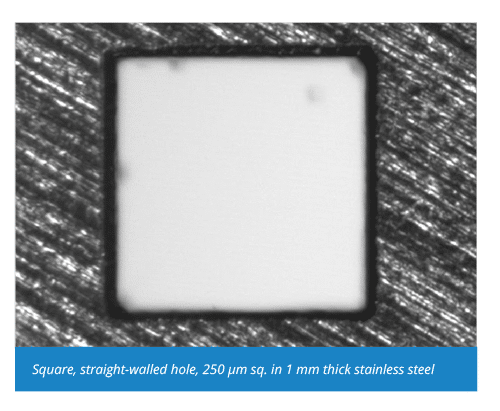

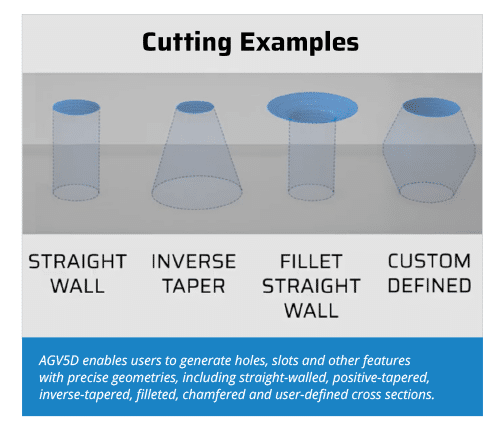

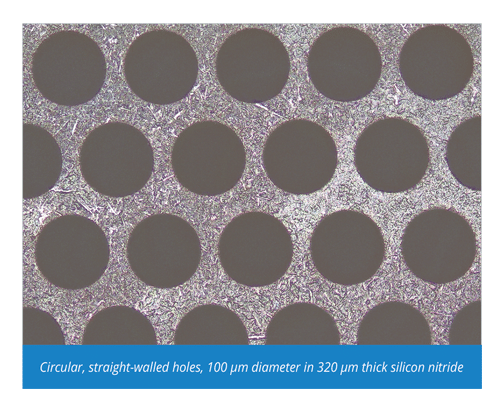

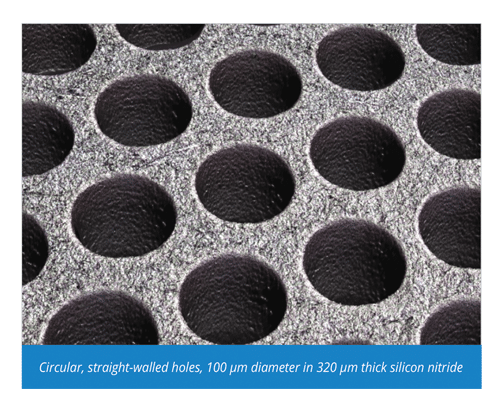

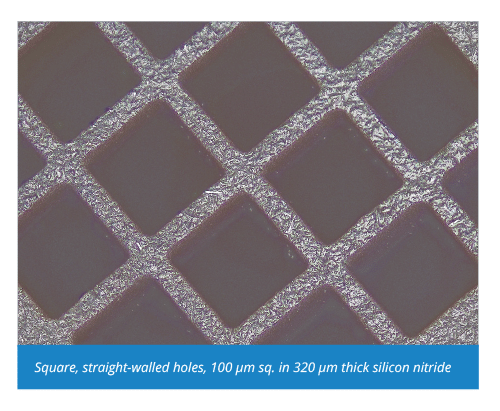

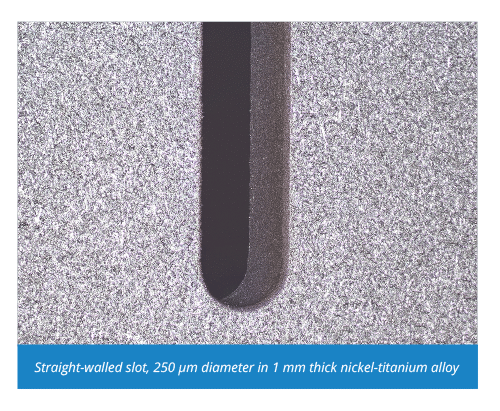

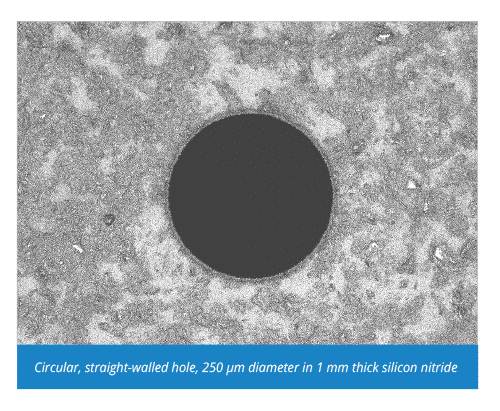

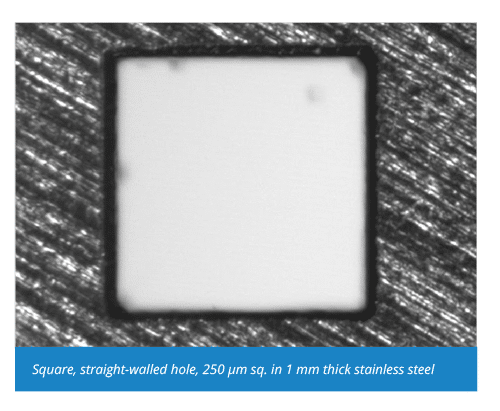

AGV5D produces extremely precise holes, slots and user-defined geometries, while maintaining exact control of the cross section.

One Controller for All Motion

Through coordination with other axes of motion using an Aerotech

controller, AGV5D offers the unique capability to generate features

larger than its field of view while maintaining the highest processing

quality. Regardless of whether the motion platform is comprised of

servo-motor or stepper-motor stages, piezoelectric nanopositioners, or

hexapods, Aerotech is the only supplier that coordinates the precession

scanner with the other motion axes, resulting in the greatest

laser-processing precision possible.

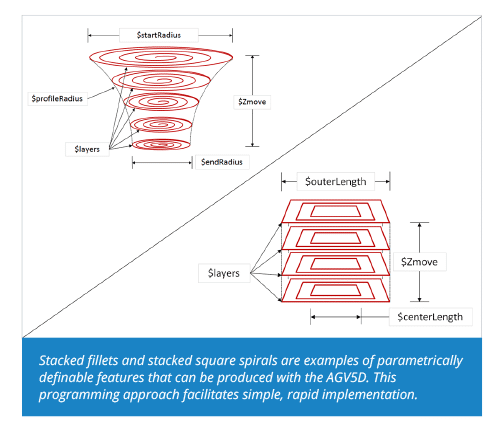

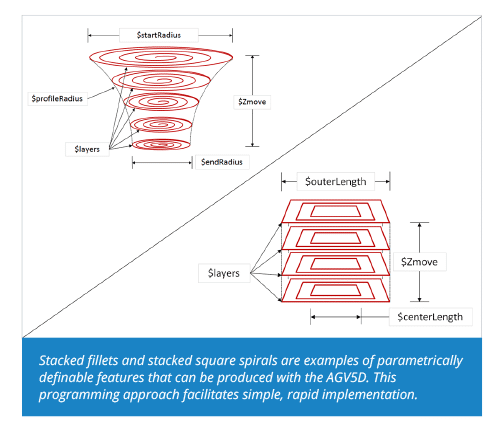

A G-code-based programming

interface gives you the ability to take control and forge your own

trajectory. Alternatively, defined functions with parametric features

and geometries are available for programming simplicity. User-accessible

diagnostic tools accelerate process development and optimization.

Simple and Flexible Integration

AGV5D is the most flexible multi-axis laser micromachining solution

available. Mounting interfaces on the front and rear faces of the

housing, along with a multidirectional beam input, simplify delivery of

the input beam. Additional kinematic mounting features on the underside

of the housing allow for repeatable dismounting and remounting of the

AGV5D, thus minimizing the need for realignment of the input beam.

Optional beam alignment modules provide a simple mechanism by which

users can set and adjust the input beam alignment and the polarization.

AGV5D

also offers great flexibility to users in that it is easy to integrate

with a diverse range of commercially available femtosecond lasers. This

is made possible through adjustable software parameters, allowing users

to compensate for laser properties such as beam divergence, diameter and

quality, which often vary among laser sources. With some relatively

quick and simple adjustments, users can set up the AGV5D with the laser

that best suits their process requirements, and can easily swap out one

laser for another.

Optimized for Industrial Use

Like all Aerotech products, AGV5D is designed for long-term durability

in production environments. Water- and air-cooling mechanisms regulate

temperature gradients within the AGV5D, thereby mitigating thermal drift

errors. The housing is sealed and includes an air purge to help keep

the optical components free from contamination, greatly reducing the

risk of damage.

Your One-Stop Precision Motion Control Partner

Since 1970, customers around the world have relied on Aerotech’s trusted

support through every step of the process: from system layout and

design, to out-of-the-box setup and support, to putting your process in

motion and keeping it moving.

Aerotech is the only supplier

offering solutions for every motion challenge. From precision mechanics

and mechatronic devices, to state-of-the-art galvo scanners and

light-manipulation technologies, to highly capable, user-friendly

controller software and hardware, you achieve greater precision and

quality with Aerotech because all components integrate seamlessly and

are coordinated through one controller.