Specifications

SM Series Specifications

| Motor Model | SM35 | SM60-VT1 | SM60-VT2 | SM100-VT1 | SM100-VT2 |

|---|---|---|---|---|---|

| NEMA Motor Frame Size | NEMA 17 | NEMA 23 | |||

| Stall Torque | 0.78 N·m (111 oz·in) | 1.23 N·m (175 oz·in) | 1.41 N·m (200 oz·in) | 1.85 N·m (262 oz·in) | 2.50 N·m (354 oz·in) |

| Rated Amps Per Phase | 3.0 A | 2.8 A | 0.84 A | 3.5 A | 0.99 A |

| Maximum Recommended Motor Voltage (1) | 35 V | 35 V | 160 V | 35 V | 160 V |

| Rotor Inertia | 1.02E-05 kg·m2(0.0014 oz·in·s2 ) | 3.00E-05 kg·m2 (0.0042 oz·in·s2 ) | 4.80E-05 kg·m2(0.0068 oz·in·s2 ) | 5.21E-05 kg·m2(0.0074 oz·in·s2) | |

| Full Step Angle | 1.8° | ||||

| Accuracy | ±0.09° | ||||

| Maximum Radial Load | 2.9 kg (6.3 lb) | 7.7 kg (17 lb) | |||

| Maximum Thrust Load | 1.0 kg (2.2 lb) | 1.5 kg (3.4 lb) | |||

| Weight | 0.50 kg (1.1 lb) | 0.70 kg (1.6 lb) | 1.0 kg (2.2 lb) | 1.2 kg (2.6 lb) | |

Maximum recommended motor voltage describes voltage seen by the motor coils

| Motor Model | SM280-VT1 | SM280-VT2 | SM465-VT1 | SM465-VT2 |

|---|---|---|---|---|

| NEMA Motor Frame Size | NEMA 34 | |||

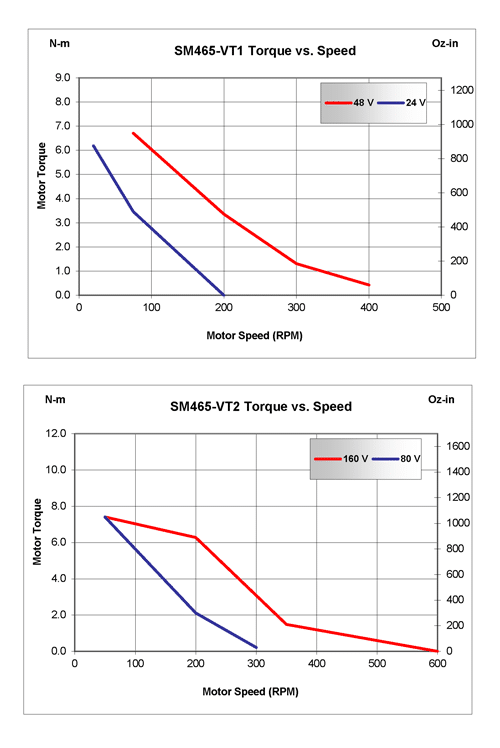

| Stall Torque | 4.50 N·m (637 oz·in) | 8.75 N·m (1238 oz·in) | 12.0 N·m (1700 oz·in) | 11.5 N·m (1637 oz·in) |

| Rated Amps Per Phase | 7.1 A | 3.04 A | 7.1 A | 2.94 A |

| Maximum Recommended Motor Voltage (1) | 48 V | 160 V | 48 V | 160 V |

| Rotor Inertia | 1.41E-04 kg·m2 (0.020 oz·in·s2) | 2.70E-04 kg·m2 (0.038 oz·in·s2) | 4.02E-04 kg·m2 (0.057 oz·in·s2) | |

| Full Step Angle | 1.8° | |||

| Accuracy | ±0.09° | |||

| Maximum Radial Load | 22.5 kg (50 lb) | |||

| Maximum Thrust Load | 6.1 kg (14 lb) | |||

| Weight | 2.3 kg (5.1 lb) | 3.8 kg (8.4 lb) | 5.4 kg (12 lb) | 5.3 kg (11.7 lb) |

Maximum recommended motor voltage describes voltage seen by the motor coils

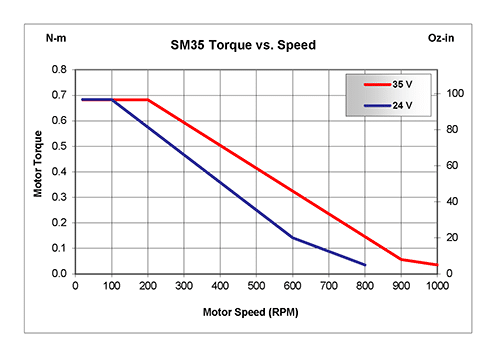

SM35 Torque

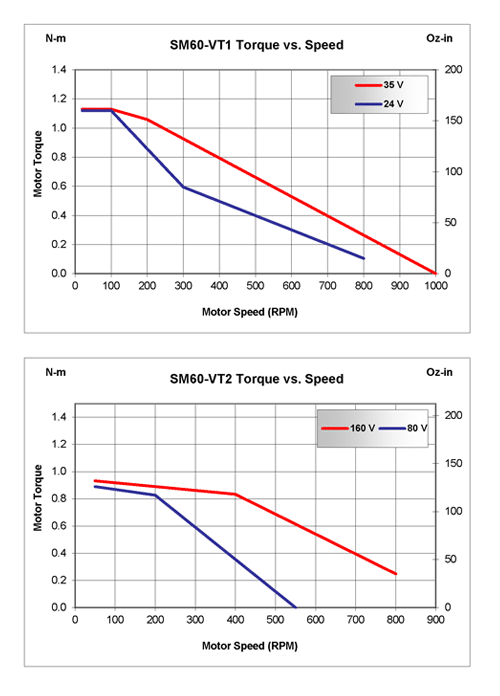

SM60 Torque

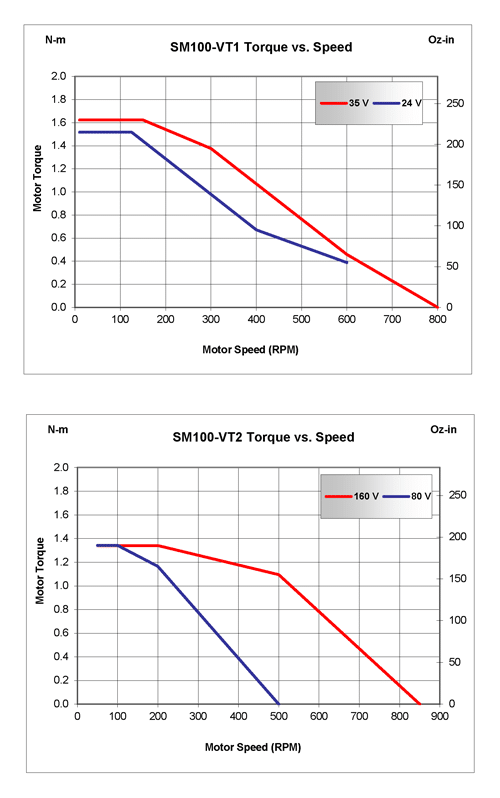

SM100 Torque

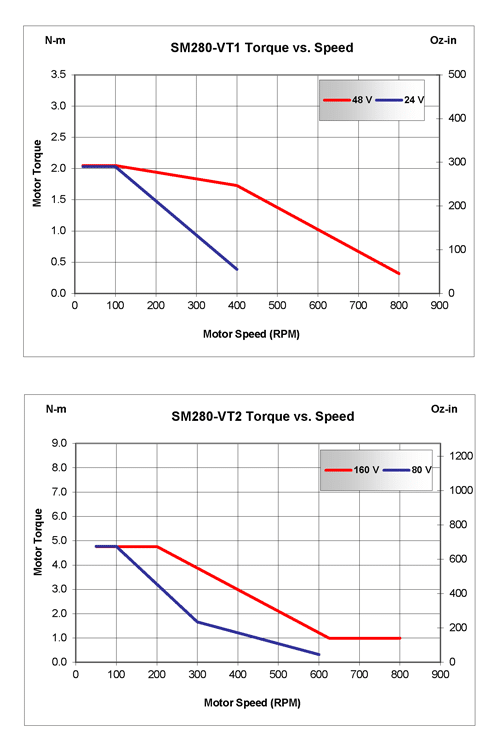

SM280 Torque

SM465 Torque

Dimensions

NEMA 17  Enlarge Image

Enlarge ImageNEMA 23  Enlarge Image

Enlarge ImageNEMA 34  Enlarge Image

Enlarge Image

Ordering Information

Ordering Example

| SM465 | -BK | -VT1 |

Ordering Options

| Stepper Motor Model | Add-Ons | Bus Voltage Selection |

|---|---|---|

| SM35 SM60 SM100 SM280 SM465 | -CN1 -BK -E1 -E2 -D | -VT1 -VT2 |

Stepper Motors: Permanent Magnet, SM Series

| Option | Description |

|---|---|

| SM35 | NEMA 17 stepper motor |

| SM60 | NEMA 23 stepper motor |

| SM100 | NEMA 23 stepper motor, high torque |

| SM280 | NEMA 34 stepper motor |

| SM465 | NEMA 34 stepper motor, high torque |

Add-Ons (Optional)

| Option | Description |

|---|---|

| -CN1 | Standard connectorized motor |

| -BK | Holding brake |

| -E1 | 1000-line incremental square-wave encoder with marker (RS-422 line-drive output) |

| -E2 | 1000-line incremental 1 Vpp amplified sine-wave encoder with marker |

| -D(1) | Viscous damper |

Viscous Damper option only available on NEMA 17 and NEMA 23 SM motors.

Bus Voltage Selection (Optional for NEMA 23 & NEMA 34 Motors Only)

| Option | Description |

|---|---|

| -VT1 | Low voltage model |

| -VT2 | High voltage model |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

|---|---|

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |