Specifications

S Series Specifications

| Motor Model | Units | S-50-39 | S-50-52 | S-50-86 | S-76-35 | S-76-85 | S-76-149 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Winding Designation | A | B | A | B | A | B | A | B | A | B | A | B | |

| Performance Specifications(1,2) | |||||||||||||

| Stall Torque, Continuous(3) | N·m | 0.20 | 0.33 | 0.56 | 0.48 | 1.60 | 2.86 | ||||||

| Peak Torque(4) | N·m | 0.82 | 1.31 | 2.26 | 1.92 | 6.41 | 11.43 | ||||||

| Rated Speed | rpm | 4,000 | 8,000 | 4,000 | 8000 | 3,000 | 8000 | 3,000 | 5,000 | 3,000 | 4,000 | 2,000 | 1,500 |

| Power Output, Continuous | W | 82.1 | 157.1 | 117.7 | 198.0 | 131.9 | 149.5 | 143.3 | 230.5 | 381.6 | 453.2 | 459.1 | 369.9 |

| Electrical Specifications(2) | |||||||||||||

| BEMF Const., Line-Line, Max | Vpk/krpm | 10.3 | 3.4 | 19.0 | 6.3 | 40 | 13.3 | 29.1 | 14.5 | 57 | 38 | 79 | 118.5 |

| Continuous Current, Stall(3) | Apk | 2.4 | 7.2 | 2.3 | 6.9 | 2.1 | 6.3 | 2.0 | 4.0 | 3.80 | 5.70 | 4.90 | 3.27 |

| Arms | 1.7 | 5.1 | 1.6 | 4.9 | 1.5 | 4.5 | 1.4 | 2.8 | 2.7 | 4.0 | 3.5 | 2.3 | |

| Peak Current, Stall(4) | Apk | 9.6 | 28.8 | 9.2 | 27.6 | 8.4 | 25.2 | 8.0 | 16.0 | 15.2 | 22.8 | 19.6 | 13.1 |

| Torque Constant(5,6) | N·m/Apk | 0.09 | 0.03 | 0.14 | 0.05 | 0.27 | 0.09 | 0.24 | 0.12 | 0.42 | 0.28 | 0.58 | 0.87 |

| N·m/Arms | 0.12 | 0.04 | 0.20 | 0.07 | 0.38 | 0.13 | 0.34 | 0.17 | 0.60 | 0.40 | 0.82 | 1.24 | |

| Motor Constant(3,5) | N·m/√W | 0.034 | 0.050 | 0.076 | 0.075 | 0.179 | 0.280 | ||||||

| Resistance, 25°C, Line-Line | Ω | 6.6 | 0.7 | 8.4 | 0.9 | 12.9 | 1.4 | 10.5 | 2.6 | 5.7 | 2.5 | 4.4 | 10.0 |

| Inductance, Line-Line | mH | 1.50 | 0.17 | 1.30 | 0.14 | 2.40 | 0.27 | 1.40 | 0.35 | 1.10 | 0.49 | 0.87 | 1.96 |

| Maximum Bus Voltage | VDC | 340 | |||||||||||

| Thermal Resistance | °C/W | 2.02 | 1.73 | 1.35 | 1.83 | 0.93 | 0.72 | ||||||

| Number of Poles | - | 8 | 14 | ||||||||||

| Mechanical Specifications | |||||||||||||

| Frameless Motor Weight | kg | 0.32 | 0.48 | 0.90 | 0.64 | 2.20 | 4.30 | ||||||

| Frameless Rotor Inertia | kg·m2 | 1.11x10-5 | 1.70x10-5 | 3.40x10-5 | 1.06x10-4 | 4.20x10-4 | 8.30x10-4 | ||||||

| Length of Winding, Frameless Motor | mm | 39.1 | 51.8 | 85.8 | 35.0 | 84.8 | 149.0 | ||||||

| Outside Diameter, Frameless Motor | mm | 50.8 | 76.0 | ||||||||||

| Rotor Bore Diameter | mm | 9.5 | 30.0 | ||||||||||

| Standards | 2011/65/EU RoHS 2 Directive | ||||||||||||

Performance is dependent upon heat sink configuration, system cooling conditions, and ambient temperature.

All performance and electrical specifications ±10%.

Values shown @ 75°C rise above a 25°C ambient temperature, with housed motor mounted to a 250 mm x 250 mm x 6 mm aluminum heat sink.

Peak torque assumes correct rms current; consult Aerotech.

Torque constant and motor constant specified at stall.

All Aerotech amplifiers are rated Apk; use torque constant in N·m/Apk when sizing.

| Motor Model | Units | S-130-39 | S-130-60 | S-130-81 | S-130-102 | S-130-123 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Winding Designation | A | B | A | B | A | B | A | B | A | B | |||

| Performance Specifications(1,2) | |||||||||||||

| Stall Torque, Continuous(3) | N·m | 2.36 | 4.18 | 5.89 | 7.69 | 8.65 | |||||||

| Peak Torque(4) | N·m | 9.42 | 16.73 | 23.55 | 30.75 | 34.61 | |||||||

| Rated Speed | rpm | 2,000 | 4,000 | 1,000 | 2,000 | 750 | 1,500 | 500 | 1,000 | 375 | 750 | ||

| Power Output, Continuous | W | 454.5 | 862.5 | 412.1 | 773.4 | 453.2 | 815.7 | 389.7 | 752.8 | 327.5 | 630.6 | ||

| Electrical Specifications(2) | |||||||||||||

| BEMF Const., Line-Line, Max | Vpk/krpm | 75.1 | 37.5 | 148.9 | 74.4 | 222.7 | 111.4 | 300.2 | 150.1 | 374.1 | 187.0 | ||

| Continuous Current, Stall(3) | Apk | 3.8 | 7.6 | 3.4 | 6.8 | 3.2 | 6.4 | 3.1 | 6.2 | 2.8 | 5.6 | ||

| Arms | 2.7 | 5.4 | 2.4 | 4.8 | 2.3 | 4.5 | 2.2 | 4.4 | 2.0 | 4.0 | |||

| Peak Current, Stall(4) | Apk | 15.2 | 30.4 | 13.6 | 27.2 | 12.8 | 25.6 | 12.4 | 24.8 | 11.2 | 22.4 | ||

| Torque Constant(5,6) | N·m/Apk | 0.62 | 0.31 | 1.23 | 0.62 | 1.84 | 0.92 | 2.48 | 1.24 | 3.09 | 1.55 | ||

| N·m/Arms | 0.88 | 0.44 | 1.74 | 0.87 | 2.60 | 1.30 | 3.51 | 1.75 | 4.37 | 2.18 | |||

| Motor Constant(3,5) | N·m/√W | 0.265 | 0.446 | 0.586 | 0.710 | 0.816 | |||||||

| Resistance, 25°C, line-line | Ω | 5.6 | 1.4 | 7.8 | 2.0 | 10.1 | 2.5 | 12.5 | 3.1 | 14.7 | 3.7 | ||

| Inductance, line-line | mH | 1.70 | 0.43 | 1.80 | 0.45 | 2.80 | 0.70 | 3.67 | 0.92 | 4.60 | 1.15 | ||

| Maximum Bus Voltage | VDC | 340 | |||||||||||

| Thermal Resistance | °C/W | 0.95 | 0.85 | 0.74 | 0.64 | 0.67 | |||||||

| Number of Poles | - | 18 | |||||||||||

| Mechanical Specifications | |||||||||||||

| Frameless Motor Weight | kg | 1.87 | 3.60 | 5.30 | 7.00 | 8.70 | |||||||

| Frameless Rotor Inertia | kg·m2 | 1.60x10-3 | 3.00x10-3 | 4.70x10-3 | 6.20x10-3 | 7.80x10-3 | |||||||

| Length of Winding, Frameless Motor | mm | 38.7 | 59.7 | 80.7 | 101.7 | 122.7 | |||||||

| Outside Diameter, Frameless Motor | mm | 128.9 | |||||||||||

| Rotor Bore Diameter | mm | 50.8 | |||||||||||

| Standards | 2011/65/EU RoHS 2 Directive | ||||||||||||

Performance is dependent upon heat sink configuration, system cooling conditions, and ambient temperature.

All performance and electrical specifications ±10%.

Values shown @ 75°C rise above a 25°C ambient temperature, with housed motor mounted to a 250 mm x 250 mm x 6 mm aluminum heat sink.

Peak torque assumes correct rms current; consult Aerotech.

Torque constant and motor constant specified at stall.

All Aerotech amplifiers are rated Apk; use torque constant in N·m/Apk when sizing.

| Motor Model | Units | S-180-44 | S-180-69 | S-180-94 | S-240-43 | S-240-63 | S-240-83 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Winding Designation | A | B | A | B | A | B | A | B | A | B | A | B | |

| Performance Specifications(1,2) | |||||||||||||

| Stall Torque, Continuous(3) | N·m | 5.99 | 11.12 | 15.93 | 10.73 | 19.71 | 29.09 | ||||||

| Peak Torque(4) | N·m | 23.98 | 44.47 | 63.70 | 42.90 | 78.82 | 116.37 | ||||||

| Rated Speed | rpm | 500 | 1000 | 500 | 1000 | 250 | 500 | 600 | 1200 | 250 | 500 | 200 | 400 |

| Power Output, Continuous | W | 302.2 | 581.2 | 570.5 | 1117.7 | 408.6 | 799.6 | 663.2 | 1303.4 | 507.1 | 996.7 | 599.0 | 1117.2 |

| Electrical Specifications(2) | |||||||||||||

| BEMF Const., Line-Line, Max | Vpk/krpm | 268.7 | 134.4 | 263.9 | 131.9 | 393.4 | 196.7 | 209.4 | 104.7 | 404.3 | 202.2 | 607.2 | 303.6 |

| Continuous Current, Stall(3) | Apk | 2.7 | 5.4 | 5.1 | 10.2 | 4.9 | 9.8 | 6.2 | 12.4 | 5.9 | 11.8 | 5.8 | 11.6 |

| Arms | 1.9 | 3.8 | 3.6 | 7.2 | 3.5 | 6.9 | 4.4 | 8.8 | 4.2 | 8.3 | 4.1 | 8.2 | |

| Peak Current, Stall(4) | Apk | 10.8 | 21.6 | 20.4 | 40.8 | 19.6 | 39.2 | 24.8 | 49.6 | 23.6 | 47.2 | 23.2 | 46.4 |

| Torque Constant(5,6) | N·m/Apk | 2.22 | 1.11 | 2.18 | 1.09 | 3.25 | 1.63 | 1.73 | 0.87 | 3.34 | 1.67 | 5.02 | 2.51 |

| N·m/Arms | 3.14 | 1.57 | 3.08 | 1.54 | 4.60 | 2.30 | 2.45 | 1.22 | 4.72 | 2.36 | 7.09 | 3.55 | |

| Motor Constant(3,5) | N·m/√W | 0.628 | 1.053 | 1.391 | 0.845 | 1.405 | 1.893 | ||||||

| Resistance, 25°C, Line-Line | Ω | 12.8 | 3.2 | 4.4 | 1.1 | 5.6 | 1.4 | 4.3 | 1.1 | 5.8 | 1.5 | 7.2 | 1.8 |

| Inductance, Line-Line | mH | 3.40 | 0.85 | 1.70 | 0.43 | 2.60 | 0.65 | 2.15 | 0.54 | 2.90 | 0.73 | 4.30 | 1.08 |

| Maximum Bus Voltage | VDC | 340 | |||||||||||

| Thermal Resistance | °C/W | 0.82 | 0.67 | 0.57 | 0.47 | 0.38 | 0.32 | ||||||

| Number of Poles | - | 18 | 26 | ||||||||||

| Mechanical Specifications | |||||||||||||

| Frameless Motor Weight | kg | 4.24 | 8.10 | 11.90 | 5.80 | 11.00 | 16.20 | ||||||

| Frameless Rotor Inertia | kg·m2 | 7.40x10-3 | 1.48x10-2 | 2.20x10-2 | 2.30x10-2 | 4.50x10-2 | 7.00x10-2 | ||||||

| Length of Winding, Frameless Motor | mm | 43.2 | 68.2 | 93.2 | 42.7 | 62.7 | 82.7 | ||||||

| Outside Diameter, Frameless Motor | mm | 180.0 | 239.2 | ||||||||||

| Rotor Bore Diameter | mm | 86.4 | 120.6 | ||||||||||

| Standards | 2011/65/EU RoHS 2 Directive | ||||||||||||

Performance is dependent upon heat sink configuration, system cooling conditions, and ambient temperature.

All performance and electrical specifications ±10%.

Values shown @ 75°C rise above a 25°C ambient temperature, with housed motor mounted to a 250 mm x 250 mm x 6 mm aluminum heat sink.

Peak torque assumes correct rms current; consult Aerotech.

Torque constant and motor constant specified at stall.

All Aerotech amplifiers are rated Apk; use torque constant in N·m/Apk when sizing.

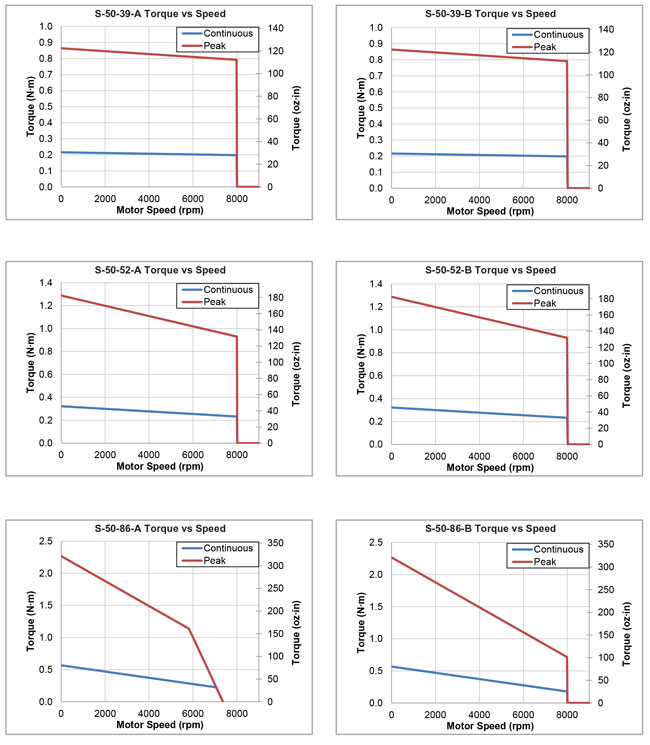

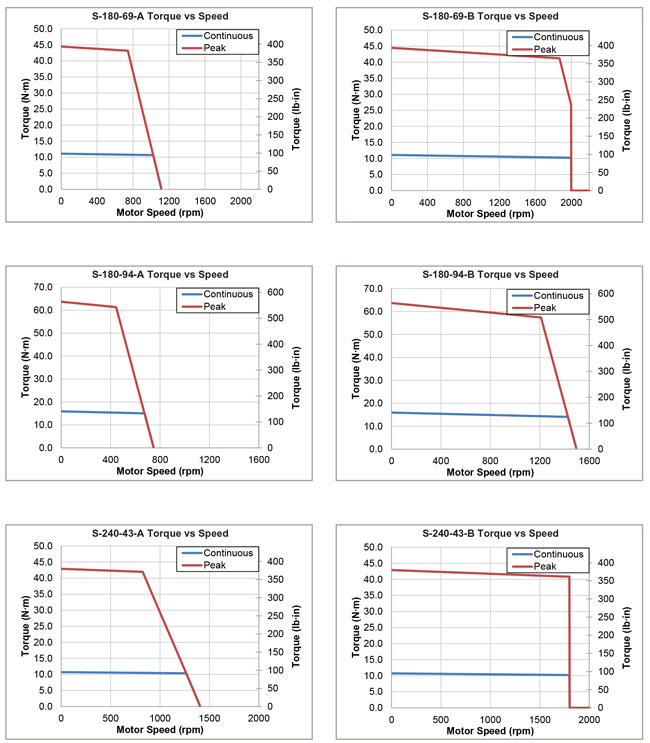

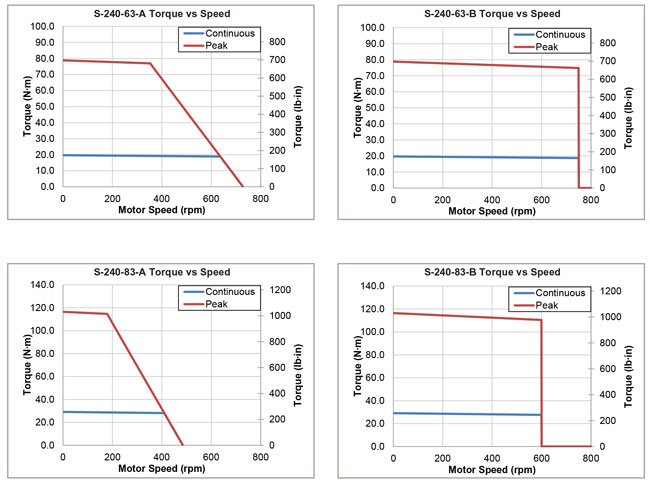

S Series Torque Curves 1

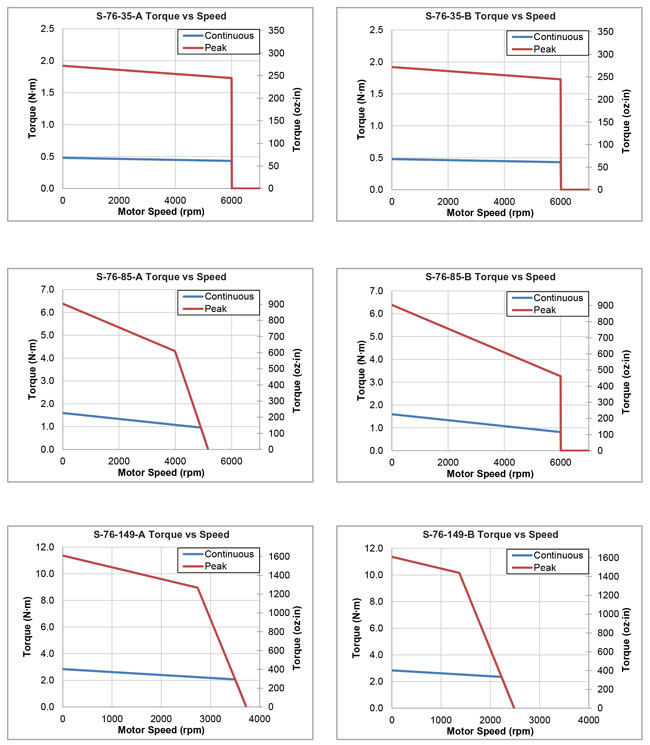

S Series Torque Curves 2

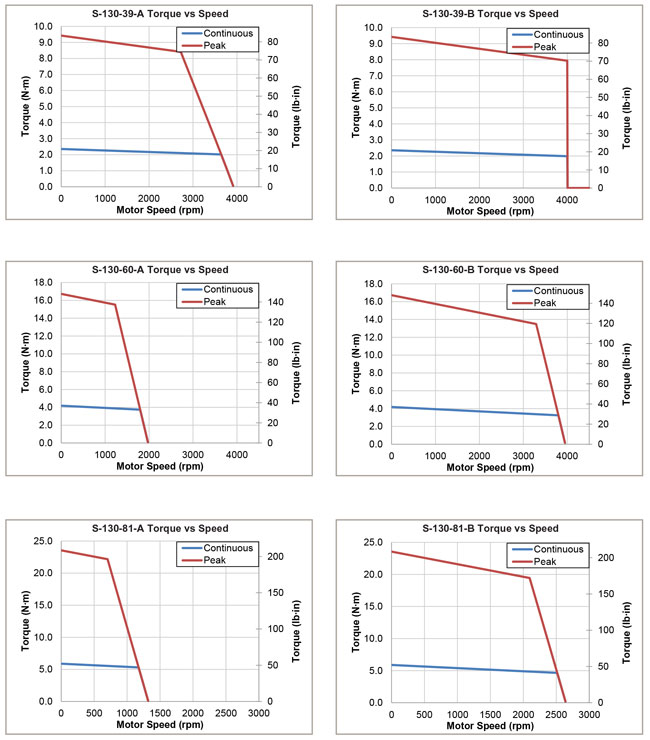

S Series Torque Curves 3

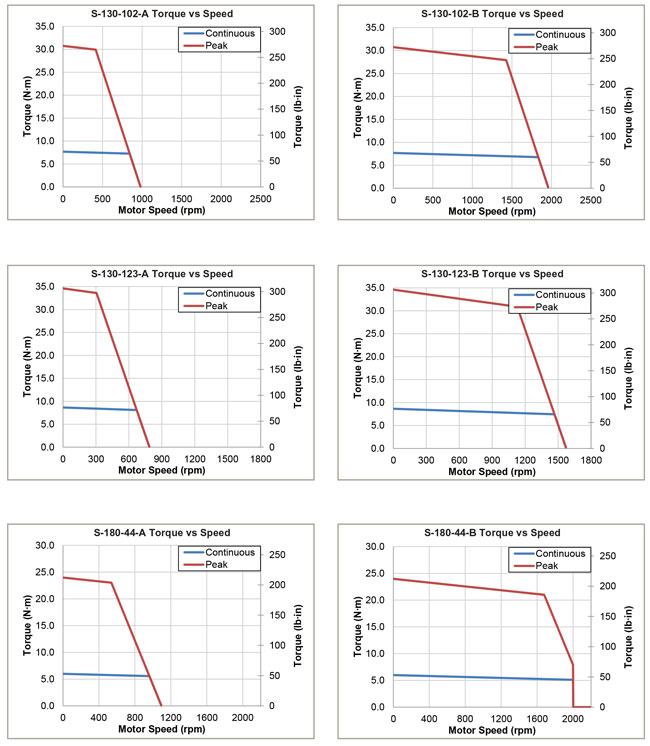

S Series Torque Curves 4

S Series Torque Curves 5

S Series Torque Curves 6

Dimensions

S-50  Enlarge Image

Enlarge ImageS-76  Enlarge Image

Enlarge ImageS-130  Enlarge Image

Enlarge ImageS-180  Enlarge Image

Enlarge ImageS-240  Enlarge Image

Enlarge Image

Ordering Information

Slotless Torque Ring "Kit" Servomotors

| Option | Description |

|---|---|

| S-50-39-A | Slotless motor, rotor, and stator, 50 mm O.D., 39 mm length. |

| S-50-52-A | Slotless motor, rotor, and stator, 50 mm O.D., 52 mm length. |

| S-50-86-A | Slotless motor, rotor, and stator, 50 mm O.D., 86 mm length. |

| S-76-35-A | Slotless motor, rotor, and stator, 76 mm O.D., 35 mm length. |

| S-76-85-A | Slotless motor, rotor, and stator, 76 mm O.D., 85 mm length. |

| S-76-149-A | Slotless motor, rotor, and stator, 76 mm O.D., 149 mm length. |

| S-130-39-A | Slotless motor, rotor, and stator, 130 mm O.D., 39 mm length. |

| S-130-60-A | Slotless motor, rotor, and stator, 130 mm O.D., 60 mm length. |

| S-130-81-A | Slotless motor, rotor, and stator, 130 mm O.D., 81 mm length. |

| S-130-102-A | Slotless motor, rotor, and stator, 130 mm O.D., 102 mm length. |

| S-130-123-A | Slotless motor, rotor, and stator, 130 mm O.D., 123 mm length. |

| S-180-44-A | Slotless motor, rotor, and stator, 180 mm O.D., 44 mm length. |

| S-180-69-A | Slotless motor, rotor, and stator, 180 mm O.D., 69 mm length. |

| S-180-94-A | Slotless motor, rotor, and stator, 180 mm O.D., 94 mm length. |

| S-240-43-A | Slotless motor, rotor, and stator, 240 mm O.D., 43 mm length. |

| S-240-63-A | Slotless motor, rotor, and stator, 240 mm O.D., 63 mm length. |

| S-240-83-A | Slotless motor, rotor, and stator, 240 mm O.D., 83 mm length. |

Note: S-Series torque ring motors include the stator w/flying leads, adjustable-phase Hall bd., and rotor w/magnets

Winding Designation (Required)

| Option | Description |

|---|---|

| -A | 76 cm (2.5 ft) flying leads std |

| -B | Optional winding. |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

|---|---|

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |