Design Features

Networkable with any Ensemble drive to control up to ten axes of piezo and/or servomotor stages

Multi-axis Position Synchronized Output (PSO) for real-time triggering of events

High-precision 20-bit sensor resolution for capacitive sensor feedback

Thermally-stable feedback circuit design

Configurable, 18-bit analog input for external feedback sensor integration or command generation

Advanced control features such as learning control, harmonic cancellation and command shaping improve tracking error and overall process throughput

Ethernet and USB 2.0 communication interfaces

Advanced Windows®-based remote diagnostics, tuning, and programming interface software

Program in AeroBasicTM using Aerotech's IDE or create custom remote interfaces with Microsoft .NET including C#, VB.NET, C++/CLI, LabVIEW®, EPICS, MATLAB®, and TANGO

CE approved; follows the 2011/65/EU RoHS 2 Directive

OEM versions available

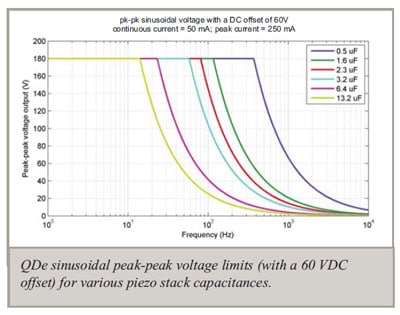

The Ensemble QDe™ is a high-performance desktop nanopositioning piezo drive designed for seamless use with the Ensemble family of drives and controllers. The QDe connects to any Ensemble controller network enabling coordinated motion between piezo stages and servo axes at much higher rates than other controller or drive products. This power and versatility make the Ensemble QDe ideal for single or multi-axis applications ranging from fundamental scientific research to advanced OEM machine systems.

Featuring a dual-core 456 MHz, double-precision, floating-point DSP, the QDe provides extreme processing power over a wide variety of applications including point-to-point motion, linear and circular interpolation, multi-axis error correction, and autofocusing. High-speed interrupts and data logging capabilities provide a real-time link to external systems. The QDe also features high-speed position latching capability and multi-axis position synchronized output (PSO) for generation of pulses based on actual position feedback in applications ranging from laser firing to acquisition system triggering.

High-Resolution and Ultra-Precise Feedback

Using the latest technology and high-resolution A/D and D/A converters, the QDe enables sub-nanometer positioning resolution at high bandwidths. The QDe capacitive sensor feedback circuitry results in exceptionally low noise levels over the full travel range. An Aerotech developed linearization method achieves linearity better than 0.01% over the full travel range in closed-loop mode. The QDe employs a proprietary capacitive sensor feedback circuit resulting in industry-leading thermal stability and exceptional long-term holding stability.

Precision I/O

In addition to the four optically-isolated digital inputs, two high-speed digital inputs and four optically-isolated digital outputs, the Ensemble QDe possesses two analog inputs and two analog outputs. One analog input, an 18-bit precision A/D, can be programmatically configured to accept an external feedback sensor or position command. This analog input also allows direct control of the high-voltage power amplifier by an external low-level analog input. Also, one 20-bit D/A analog output can be programmatically configured for position or voltage monitoring at very high resolutions.

Advanced Software and Control Features

The Ensemble QDe uses PID servo loops with advanced feedforward and multiple integrators coupled with eight programmable filters to supply the user with all necessary tools needed to optimize motion performance. Additional software options such as the Dynamic Controls Toolbox and Motion Designer packages make available a host of advanced, yet easy-to-use, tools such as Learning Control, Harmonic Cancellation, Command Shaping, and Cross-Axis Feedforward to improve tracking errors and provide faster step-and-settle times.

Learn more about our controls and software HERE.

Powerful Programming and Software Drivers

Monitor and control all aspects of the positioning system, no matter how complex, through the Ensemble GUI Integrated Development Environment software. Advanced tuning utilities minimize startup time by allowing easy optimization of motion axes. Functional programs that can be modified and used in customer applications are included in the online Help. Pre-coded LabVIEW® VIs, AeroBasic™ programming functionality, MATLAB® library, .NET tools for C#, VB.NET and C++/CLI or C make the Ensemble even easier to use. See the Ensemble Control home page for detailed information on software capabilities and ordering options.

Automatic Parameter Configuration

Aerotech’s piezo stages include our time-saving “FlashConfig” feature that stores all of the parametric information required to operate the stage. Upon plug-in, the QDe automatically identifies the connected stage. All operation parameters, including axis calibration data and software parameters, are /uploaded into the Ensemble QDe. This ensures faster setup and avoids errors that can result in substandard performance. “FlashConfig” provides true “plug and play” operation of your Aerotech stage.

Thermal Stability Comparison

Piezo controller design can have a significant effect on thermal stability causing excessive error in precision motion applications. See our Technical Note where we briefly describe some techniques used for controlling thermal effects and compare the thermal stability of our piezo control electronics with a competitive design.