Specifications

APR Series Specifications

| Model | APR150DR-115 | APR150DR-135 | APR150DR-180 | ||

|---|---|---|---|---|---|

| Travel | Continuous (Optional 270° Max Limited) | ||||

| Accuracy | -E1, -E2, -E3, -E4 Feedback Options | Uncalibrated | 45 arc sec | ||

| Calibrated | 4 arc sec | ||||

| -E5, -E6 Feedback Options | Uncalibrated | N/A | 4 arc sec | ||

| Calibrated | N/A | 2 arc sec | |||

| Resolution (Minimum Incremental Motion) | 0.08 arc sec | ||||

| Bidirectional Repeatability(1) | 1.50 arc sec | ||||

| Unidirectional Repeatability | 0.75 arc sec | ||||

| Total Tilt Error Motion(1) | 2.00 arc sec | ||||

| Total Axial Error Motion(1) | 1.50 µm | ||||

| Total Radial Error Motion(1) | 1.50 µm | ||||

| Maximum Speed(3) | With -M1 Motor Option | 600 rpm | |||

| With -M2 Motor Option | 800 rpm | ||||

| Maximum Acceleration | 450 rad/s2 | 625 rad/s2 | 805 rad/s2 | ||

| Aperture | 50 mm | ||||

| Maximum Torque (Continuous) | 2.85 N·m | 5.06 N·m | 9.29 N·m | ||

| Load Capacity | Axial | 45 kg | |||

| Radial | 32 kg | ||||

| Rotor Inertia (Unloaded) | 0.0047 kg·m2 | 0.0060 kg·m2 | 0.0086 kg·m2 | ||

| Stage Mass(4) | 6.5 kg | 8.5 kg | 12.3 kg | ||

| Material | Aluminum; Hardcoat/Anodize Finish | ||||

| MTBF (Mean Time Between Failure) | 20,000 hours | ||||

Certified with each stage.

All error motion specifications are measured at 60 rpm.

Maximum speed listed is stage and motor dependent (assuming a 340 V bus). Actual speed may be lower due to motor back emf or encoder bandwidth (see Encoder Bandwidth table). Consult an Aerotech Applications Engineer for more details.

Mass listed is for the standard stage option (no brake and no tabletop). Consult Aerotech if brake and tabletop masses are desired.

APR Series Specifications

| Model | APR200DR-155 | APR200DR-185 | APR260DR-160 | APR260DR-180 | ||

|---|---|---|---|---|---|---|

| Travel | Continuous (Optional 270° Max Limited) | |||||

| Accuracy | -E1, -E2, -E3, -E4 Feedback Options | Uncalibrated | 33 arc sec | 25 arc sec | ||

| Calibrated | 3 arc sec | 2 arc sec | ||||

| -E5, -E6 Feedback Options | Uncalibrated | 3 arc sec | 2 arc sec | |||

| Calibrated | 1.75 arc sec | 1.50 arc sec | ||||

| Resolution (Minimum Incremental Motion) | 0.06 arc sec | 0.04 arc sec | ||||

| Bidirectional Repeatability(1) | 1.00 arc sec | 0.75 arc sec | ||||

| Unidirectional Repeatability | 0.50 arc sec | 0.50 arc sec | ||||

| Total Tilt Error Motion(1) | 2.00 arc sec | |||||

| Total Axial Error Motion(1) | 1.50 µm | |||||

| Total Radial Error Motion(1) | 1.50 µm | |||||

| Maximum Speed(3) | With -M1 Motor Option | 600 rpm | 375 rpm | |||

| With -M2 Motor Option | 800 rpm | N/A | ||||

| Maximum Acceleration | 380 rad/s2 | 440 rad/s2 | 175 rad/s2 | 215 rad/s2 | ||

| Aperture | 75 mm | 100 mm | ||||

| Maximum Torque (Continuous) | 11.12 N·m | 15.93 N·m | 19.71 N·m | 29.09 N·m | ||

| Load Capacity | Axial | 205 kg | 250 kg | |||

| Radial | 100 kg | 135 kg | ||||

| Rotor Inertia (Unloaded) | 0.026 kg·m2 | 0.032 kg·m2 | 0.10 kg·m2 | 0.12 kg·m2 | ||

| Stage Mass(4) | 17.8 kg | 22 kg | 29.8 kg | 35.4 kg | ||

| Material | Aluminum; Hardcoat/Anodize Finish | |||||

| MTBF (Mean Time Between Failure) | 20,000 hours | |||||

Certified with each stage.

All error motion specifications are measured at 60 rpm.

Maximum speed listed is stage and motor dependent (assuming a 340 V bus). Actual speed may be lower due to motor back emf or encoder bandwidth (see Encoder Bandwidth table). Consult an Aerotech Applications Engineer for more details.

Mass listed is for the standard stage option (no brake and no tabletop). Consult Aerotech if brake and tabletop masses are desired.

Recommended Controller

| Multi-Axis | A3200 | Ndrive HLe/Ndrive HPe/Ndrive MP10/Ndrive CP10/Npaq |

| Ensemble | Ensemble HLe/Ensemble HPe/Ensemble MP10/Ensemble CP10/Epaq | |

| Single Axis | Soloist | Soloist HLe/Soloist HPe/Soloist MP10/Soloist CP10 |

HPe, HLe, or CP drive required with -E4 encoder option.

HPe or HLe drive required with -E5 and -E6 encoder options.

Max Speed (rpm) Per Encoder Bandwidth

| Model | -E1 | -E4 | -E2, -E5 | -E3, E6 |

|---|---|---|---|---|

| APR150DR | Motor Limited | Motor Limited | 118 | 11 |

| APR200DR | Motor Limited | Motor Limited | 82 | 8 |

| APR260DR | 375 | 375 | 59 | 5 |

Motor & Resolution Specifications

| Model | APR150DR-115 | APR150DR-135 | APR150DR-180 |

|---|---|---|---|

| Drive System | Slotless, brushless, direct-drive rotary motor | ||

| Fundamental Resolution (Lines/Rev) | 16384 | ||

| -E1 Resolution | 0.020/0.005 arc seconds | ||

| -E4 Resolution | 0.000301 arc seconds | ||

| -E5 Resolution | 0.079 arc seconds | ||

| -E6 Resolution | 0.0079 arc seconds | ||

| Maximum Bus Voltage | 340 VDC | ||

| Limit Switches | Optional – specified at time of order; 5 VDC Normally Closed | ||

| Home Switch | 5 VDC Normally Closed | ||

RE-AS shows 4000MXU/16000MXH total multiplication (including quadrature).

REH not available with APR150DR-115.

Motor & Resolution Specifications

| Model | APR200DR-155 | APR200DR-185 | APR260DR-160 | APR260DR-180 |

|---|---|---|---|---|

| Drive System | Slotless, brushless, direct-drive rotary motor | |||

| Fundamental Resolution (Lines/Rev) | 23600 | 32768 | ||

| -E1 Resolution | 0.014/0.0034 arc seconds | 0.010/0.0025 arc seconds | ||

| -E4 Resolution | 0.000301 arc seconds | 0.000301 arc seconds | ||

| -E5 Resolution | 0.055 arc seconds | 0.04 arc seconds | ||

| -E6 Resolution | 0.0055 arc seconds | 0.004 arc seconds | ||

| Maximum Bus Voltage | 340 VDC | |||

| Limit Switches | Optional – specified at time of order; 5 VDC Normally Closed | |||

| Home Switch | 5 VDC Normally Closed | |||

RE-AS shows 4000MXU/16000MXH total multiplication (including quadrature).

REH not available with APR150DR-115.

Load Plots 150

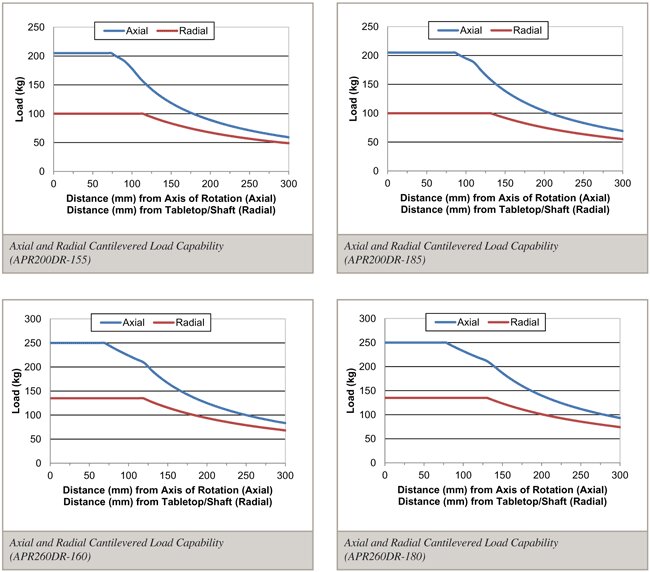

Load Plots 200/260

Dimensions

APR-150  Enlarge Image

Enlarge ImageAPR-200  Enlarge Image

Enlarge ImageAPR-260  Enlarge Image

Enlarge Image

Ordering Information

APR High-Precision Mechanical Bearing Rotary Stage

| Option | Description |

|---|---|

| APR150DR-115 | APR150DR-115 high-precision mechanical bearing rotary stage |

| APR150DR-135 | APR150DR-135 high-precision mechanical bearing rotary stage |

| APR150DR-180 | APR150DR-180 high-precision mechanical bearing rotary stage |

| APR200DR-155 | APR200DR-155 high-precision mechanical bearing rotary stage |

| APR200DR-185 | APR200DR-185 high-precision mechanical bearing rotary stage |

| APR260DR-160 | APR260DR-160 high-precision mechanical bearing rotary stage |

| APR260DR-180 | APR260DR-180 high-precision mechanical bearing rotary stage |

Feedback (Required)

| Option | Description |

|---|---|

| -E1 | Incremental encoder, 1 Vpp |

| -E2 | Incremental encoder, TTL, x1000 interpolation |

| -E3 | Incremental encoder, TTL, x10000 interpolation |

| -E4 | Absolute encoder |

| -E5 | High-accuracy incremental encoder, TTL, x1000 interpolation |

| -E6 | High-accuracy incremental encoder, TTL, x10000 interpolation |

*Note: -E5 and -E6 options are not available with APR150DR-115.

Motor (Required)

| Option | Description |

|---|---|

| -M1 | Low current, -A winding |

| -M2 | Low voltage, -B winding |

*Note: -M2 option not available with APR260DR models.

Tabletop (Optional)

| Option | Description |

|---|---|

| -TT1 | Metric graduated tabletop |

| -TT2 | English graduated tabletop |

Travel (Required)

| Option | Description |

|---|---|

| -TRCNT | Continuous travel |

| -TR010 | Limited travel, +/- 5 degrees |

| -TR020 | Limited travel, +/- 10 degrees |

| -TR040 | Limited travel, +/- 20 degrees |

| -TR060 | Limited travel, +/- 30 degrees |

| -TR080 | Limited travel, +/- 40 degrees |

| -TR100 | Limited travel, +/- 50 degrees |

| -TR120 | Limited travel, +/- 60 degrees |

| -TR140 | Limited travel, +/- 70 degrees |

| -TR160 | Limited travel, +/- 80 degrees |

| -TR180 | Limited travel, +/- 90 degree |

| -TR200 | Limited travel, +/- 100 degrees |

| -TR220 | Limited travel, +/- 110 degrees |

| -TR240 | Limited travel, +/- 120 degrees |

| -TR270 | Limited travel, +/- 135 degrees |

*Note: -TRxxx options contain an extra 1.5 degrees between the nominal travel and the electrical limit on each side. (Ex: -TR270 contains +/- 135 degrees of nominal travel, with +/-136.5 degrees of travel between electrical limits.)

Hardstops (Optional)

| Option | Description |

|---|---|

| -HS | Mechanical hard stops |

*Note: -HS option requires the selection of a Tabletop option (-TTx) and a Limited Travel option (-TRxxx).

Brake (Optional)

| Option | Description |

|---|---|

| -BK | Holding brake |

*Note: -BK option not available with APR260DR models.

Metrology (Required)

| Option | Description |

|---|---|

| -PL3 | Metrology, uncalibrated with performance plots |

| -PL4 | Metrology, calibrated (HALAR) with performance plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

|---|---|

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |