Specifications

ADRT Series Specifications

| Model | ADRT100-85 | ADRT100-135 | ADRT150-115 | ADRT150-135 | ADRT150-180 | |

|---|---|---|---|---|---|---|

| Maximum Torque (Continuous) | 0.48 N·m | 1.6 N·m | 2.85 N·m | 5.06 N·m | 9.29 N·m | |

| Bus Voltage(1) | Up to 340 VDC | |||||

| Accuracy(2,3) | Uncalibrated | 60 arc sec | ||||

| Calibrated | 5 arc sec | |||||

| Repeatability(3) | 3 arc sec | |||||

| Axial Error Motion | 5 µm | |||||

| Radial Error Motion(4) | 5 µm | |||||

| Tilt Error Motion | 10 arc sec | |||||

| Height | 85 mm | 135 mm | 115 mm | 135 mm | 180 mm | |

| Aperture | 13 mm | 50 mm | ||||

| Radial Load(5) | 10 kg | 25 kg | ||||

| Axial Load | 15 kg | 30 kg | ||||

| Rated Speed | 1500 rpm | 600 rpm | ||||

| Inertia | 0.00028 kg·m2 | 0.00067 kg·m2 | 0.003379 kg·m2 | 0.004958 kg·m2 | 0.008118 kg·m2 | |

| Mass | 2.0 kg | 3.6 kg | 5.3 kg | 6.9 kg | 10.2 kg | |

| Finish | Table | Hardcoat | ||||

| Stage | Black Anodize | |||||

Bus voltage for ADRT100 with -25D connector is limited to 160 V.

Calibrated accuracy requires -PL2 option and Aerotech controls.

Repeatability and accuracy are dependent on encoder resolution. To achieve the listed specifications, encoder resolution must be 0.36 arc sec or less.

Specifications are for single-axis systems. Performance of multi-axis systems is payload and workpoint dependent. Consult factory for multi-axis or non-standard applications.

Moment load based on 5 year continuous rotation at 250 rpm with maximum axial load applied. Larger moment loads possible for low speed and/or low duty cycle applications. Consult Aerotech for additional information.

ADRT Series Specifications

| Model | ADRT200-155 | ADRT200-185 | ADRT260-160 | ADRT260-180 | |

|---|---|---|---|---|---|

| Maximum Torque (Continuous) | 11.12 N·m | 15.93 N·m | 19.71 N·m | 29.09 N·m | |

| Bus Voltage | Up to 340 VDC | ||||

| Accuracy(1,2) | Uncalibrated | 60 arc sec | |||

| Calibrated | 5 arc sec | ||||

| Repeatability(2) | 3 arc sec | ||||

| Axial Error Motion | 5 µm | ||||

| Radial Error Motion(3) | 5 µm | ||||

| Tilt Error Motion | 10 arc sec | ||||

| Height | 155 mm | 160 mm | |||

| Aperture | 75 mm | 100 mm | |||

| Radial Load(4) | 80 kg | 110 kg | |||

| Axial Load | 140 kg | 170 kg | |||

| Rated Speed | 600 rpm | 375 rpm | |||

| Inertia | 0.020991 kg·m2 | 0.027666 kg·m2 | 0.066488 kg·m2 | 0.08566 kg·m2 | |

| Mass | 13.4 kg | 16.7 kg | 25.4 kg | 30.6 kg | |

| Finish | Table | Hardcoat | |||

| Stage | Black Anodize | ||||

Calibrated accuracy requires -PL2 option and Aerotech controls.

Repeatability and accuracy are dependent on encoder resolution. To achieve the listed specifications, encoder resolution must be 0.36 arc sec or less.

Specifications are for single-axis systems. Performance of multi-axis systems is payload and workpoint dependent. Consult factory for multi-axis or non-standard applications.

Moment load based on 5 year continuous rotation at 250 rpm with maximum axial load applied. Larger moment loads possible for low speed and/or low duty cycle applications. Consult Aerotech for additional information.

ADRT Maximum Speeds for Encoder Option

| Encoder Option | ADRT100 | ADRT150 | ADRT200 | ADRT260 |

|---|---|---|---|---|

| -E1/-E2/-E3/-E4 | 1500 rpm | 600 rpm | 600 rpm | 375 rpm |

| -E5 | 800 rpm | 600 rpm | 500 rpm | 375 rpm |

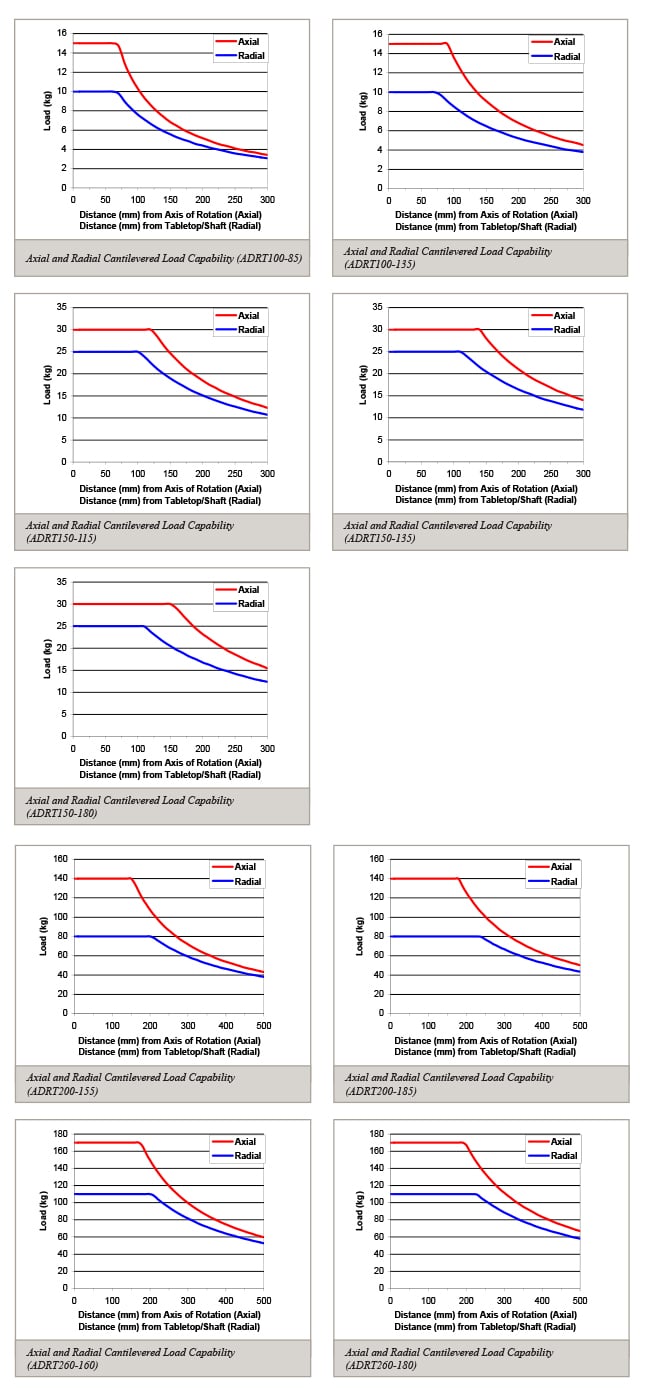

ADRT Axial & Radial Cantilevered Load Capabilities

Dimensions

ADRT100  Enlarge Image

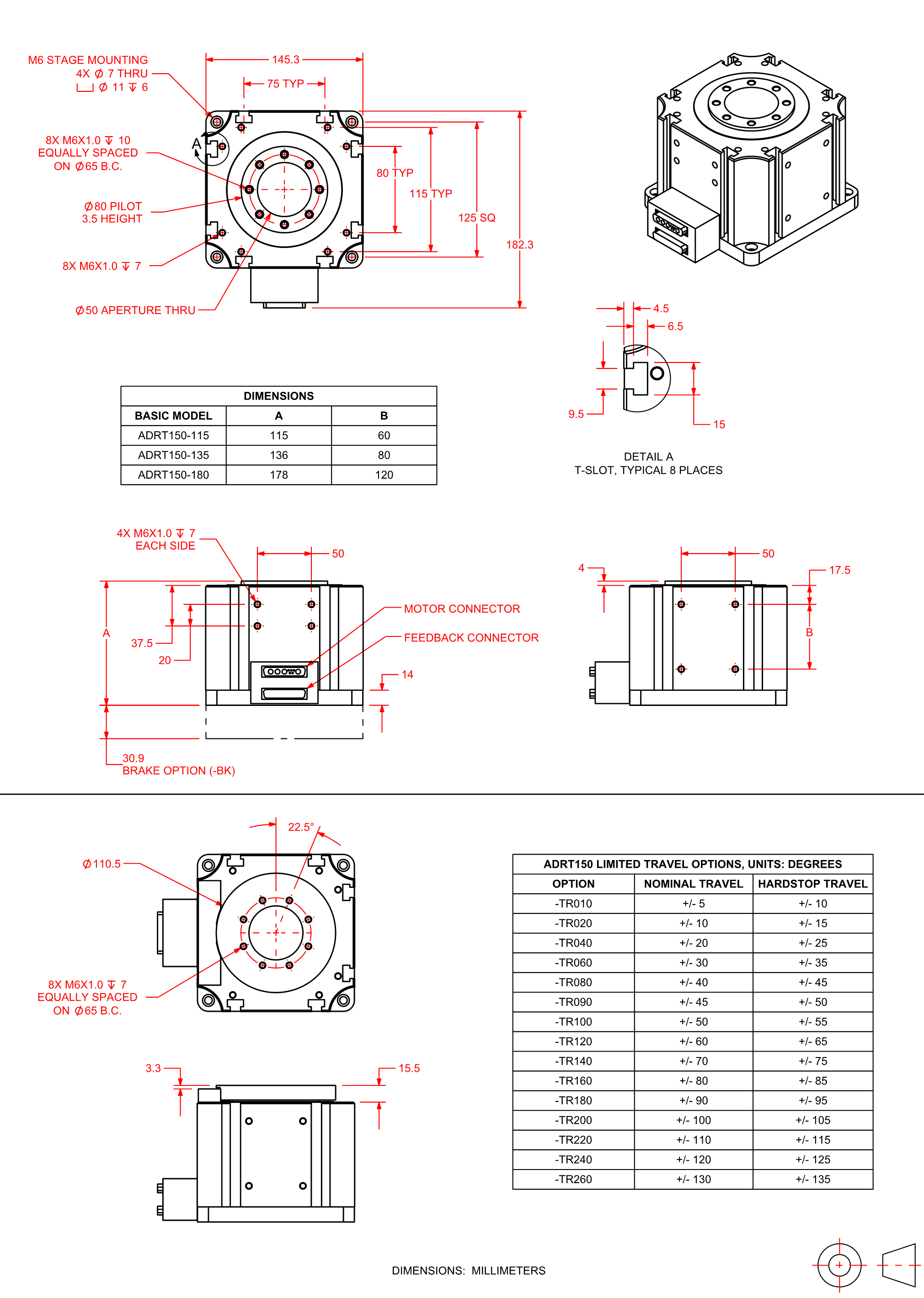

Enlarge ImageADRT150  Enlarge Image

Enlarge ImageADRT150 Limits/Hardstops  Enlarge Image

Enlarge ImageADRT200  Enlarge Image

Enlarge ImageADRT200 Limits/Hardstops  Enlarge Image

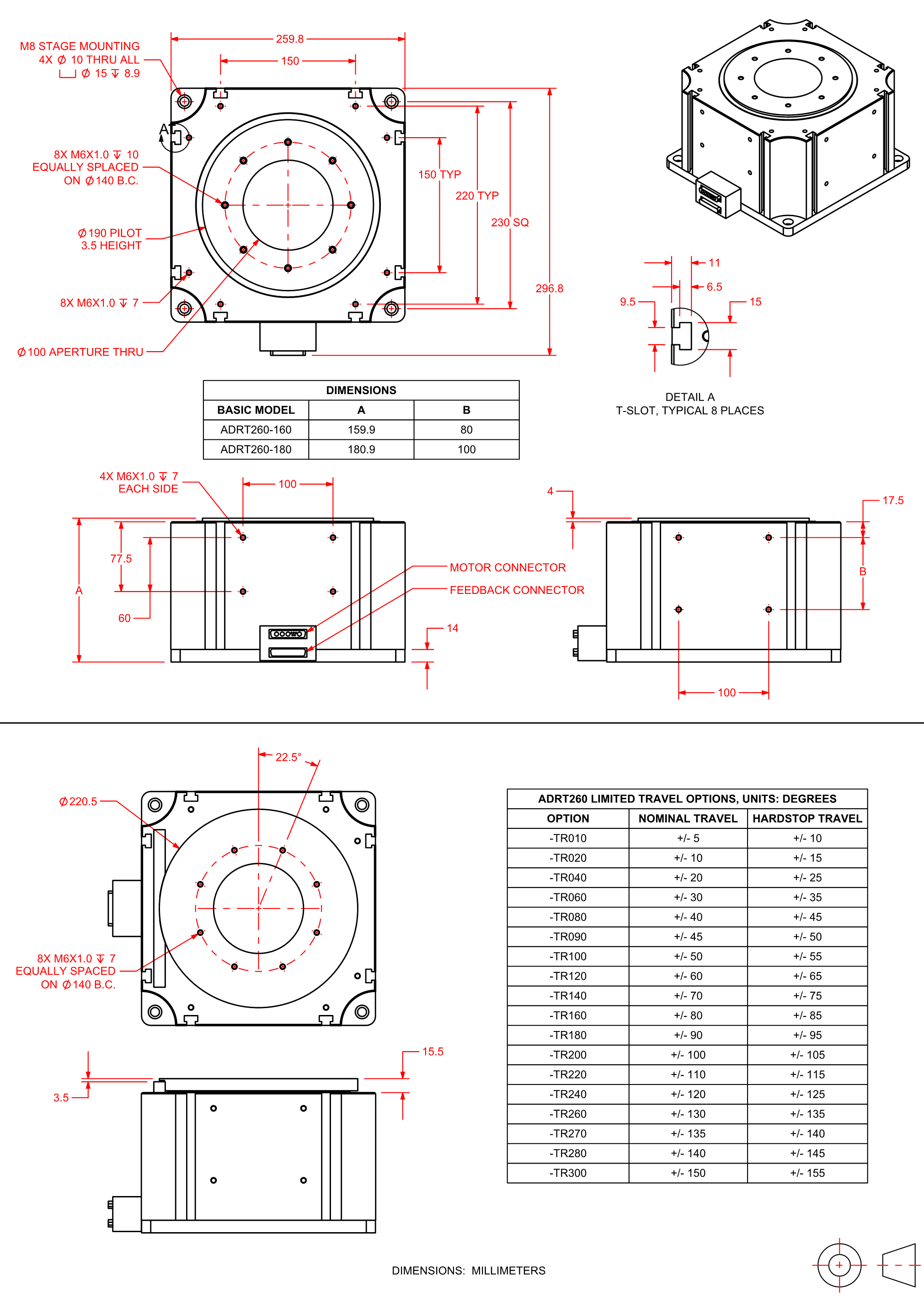

Enlarge ImageADRT260  Enlarge Image

Enlarge ImageADRT260 Limits/Hardstops  Enlarge Image

Enlarge Image

Ordering Information

ADRT Mechanical-Bearing Direct-Drive Rotary Stage

| Option | Description |

|---|---|

| ADRT100 | ADRT100 mechanical-bearing direct-drive rotary stage |

| ADRT150 | ADRT150 mechanical-bearing direct-drive rotary stage |

| ADRT200 | ADRT200 mechanical-bearing direct-drive rotary stage |

| ADRT260 | ADRT260 mechanical-bearing direct-drive rotary stage |

Stage Height (Required)

| Option | Description |

|---|---|

| -85 | 85 mm stage height - Only available for ADRT100 |

| -115 | 115 mm stage height - Only available for ADRT150 |

| -135 | 135 mm stage height - Only available for ADRT100 and ADRT150 |

| -155 | 155 mm stage height - Only available for ADRT200 |

| -160 | 160 mm stage height - Only available for ADRT260 |

| -180 | 180 mm stage height - Only available for ADRT150 and ADRT 260 |

| -185 | 185 mm stage height - Only available for ADRT200 |

Motor (Required)

| Option | Description |

|---|---|

| -M1 | Low current, -A winding |

| -M2 | Low voltage, -B winding |

Note: Only available for ADRT260.

Feedback (Required)

| Option | Description |

|---|---|

| -E1 | Incremental encoder, 1 Vpp |

| -E2 | Incremental encoder, TTL, x5 interpolation |

| -E3 | Incremental encoder, TTL, x10 interpolation |

| -E4 | Incremental encoder, TTL, x25 interpolation |

| -E5 | Incremental encoder, TTL, x50 interpolation |

Connector (Required)

| Option | Description |

|---|---|

| -CN1 | 4-pin HPD motor and 25-pin D Fbk connectors |

| -CN2 | 25-pin D motor and 25-pin D Fbk connectors |

Note: Only available for ADRT100.

Rear Seal (Optional)

| Option | Description |

|---|---|

| -SL | Rear seal |

Note: Only available for ADRT100.

Air Purge (Optional)

| Option | Description |

|---|---|

| -PR | Air-purge fitting |

Note: Only available for ADRT100.

Brake (Optional)

| Option | Description |

|---|---|

| -BK | Holding brake |

Note: Only available for the ADRT150 and the ADRT200. Not available with limited travel option.

Limited Travel (Optional)

| Option | Description |

|---|---|

| -TR010 | Limited travel, +/- 5 degrees |

| -TR020 | Limited travel, +/- 10 degrees |

| -TR040 | Limited travel, +/- 20 degrees |

| -TR060 | Limited travel, +/- 30 degrees |

| -TR080 | Limited travel, +/- 40 degrees |

| -TR090 | Limited travel, +/- 45 degrees |

| -TR100 | Limited travel, +/- 50 degrees |

| -TR120 | Limited travel, +/- 60 degrees |

| -TR140 | Limited travel, +/- 70 degrees |

| -TR160 | Limited travel, +/- 80 degrees |

| -TR180 | Limited travel, +/- 90 degrees |

| -TR200 | Limited travel, +/- 100 degrees |

| -TR220 | Limited travel, +/- 110 degrees |

| -TR240 | Limited travel, +/- 120 degrees |

| -TR260 | Limited travel, +/- 130 degrees |

| -TR270 | Limited travel, +/- 135 degrees - Only available on ADRT200 and ADRT260 |

| -TR280 | Limited travel, +/- 140 degrees - Only available on ADRT200 and ADRT260 |

| -TR300 | Limited travel, +/- 150 degrees - Only available on ADRT200 and ADRT260 |

Note: Not available with ADRT100. Not available with brake option.

-TRxxx options include electrical limits and mechanical hardstops. There are an extra 1.5 degrees per side between the nominal travel and the electrical limits, and an extra 5 degrees per side between the nominal travel and mechanical hardstops. (Ex: TR90 has +/- 45 degrees of nominal travel, with +/- 46.5 degrees of travel between electrical limits and +/- 50 degrees of travel between mechanical hardstops.)

Metrology (Required)

| Option | |

|---|---|

| -PL0 | No metrology performance plots |

| -PL1 | Metrology, uncalibrated with performance plots |

| -PL2 | Metrology, calibrated (HALAR) with performance plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

|---|---|

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |