Specifications

Mechanical Specifications

| Model | ANT95LZ-025 | ANT95LZ-050 | |

|---|---|---|---|

| Travel | 25 mm | 50 mm | |

| Accuracy(1) | Basic | ±4.0 µm | ±4.0 µm |

| PLUS | ±300 nm | ±300 nm | |

| Resolution (Minimum Incremental Motion) | 2 nm | 2 nm | |

| Bidirectional Repeatability(1) | Basic | ±100 nm | ±100 nm |

| PLUS | ±75 nm | ±75 nm | |

| Unidirectional Repeatability | ±50 nm | ±50 nm | |

| Straightness(1) | ±2.25 µm | ±3.0 µm | |

| Flatness(1) | ±3.5 µm | ±4.0 µm | |

| Pitch | 10 arc sec | 10 arc sec | |

| Roll | 10 arc sec | 10 arc sec | |

| Yaw | 5 arc sec | 5 arc sec | |

| Maximum Speed | 200 mm/s | 200 mm/s | |

| Maximum Acceleration | 1 g (No Load) | 1 g (No Load) | |

| In-Position Stability(2) | <2 nm | <2 nm | |

| Maximum Force (Continuous) | 7.75 N | 9.5 N | |

| Load Capacity(3) | Vertical | 5.0 kg | 5.0 kg |

| Moving Mass | 0.46 kg | 0.52 kg | |

| Stage Mass | 1.9 kg | 2.5 kg | |

| Material | Aluminum Body/Black Hardcoat Finish | ||

| MTBF (Mean Time Between Failure) | 30,000 Hours | ||

Certified with each stage.

In-Position Jitter listing is 3 sigma value.

Axis orientation for on-axis loading is listed.

Air supply must be clean, dry to 0°F dewpoint and filtered to 0.25 µm or better; recommend nitrogen at 99.9% purity. Supply pressure is determined by the amount of payload carried by the stage.

• Specifications are for single-axis systems measured 25 mm above the tabletop. Performance of combined multi-axis systems is payload and workpoint dependent. Consult factory for multi-axis or non-standard applications.

• -PLUS requires the use of an Aerotech controller.

Electrical Specifications

| Drive System | Brushless Linear Servomotor |

| Feedback | Noncontact Linear Encoder |

| Maximum Bus Voltage | ±40 VDC |

| Limit Switches | 5 V, Normally Closed |

| Home Switch | Near Center |

Recommended Controllers

| Multi-Axis | A3200 | Npaq MXR Npaq MR-MXH Ndrive ML-MXH |

| Ensemble | Epaq MXH Epaq MR-MXH Ensemble ML-MXH | |

| Single Axis | Soloist | Soloist ML-MXH |

Linear amplifiers are required to achieve the listed specifications. Other options are available.

Note: To ensure the achievement and repeatability of specifications over an extended period of time environmental temperature must be controlled to within 0.25ºC/24 hours. If this is not possible, alternate products are available. Please consult Aerotech for more information.

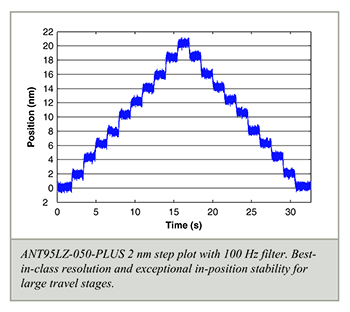

ANT95LZ Step Plot

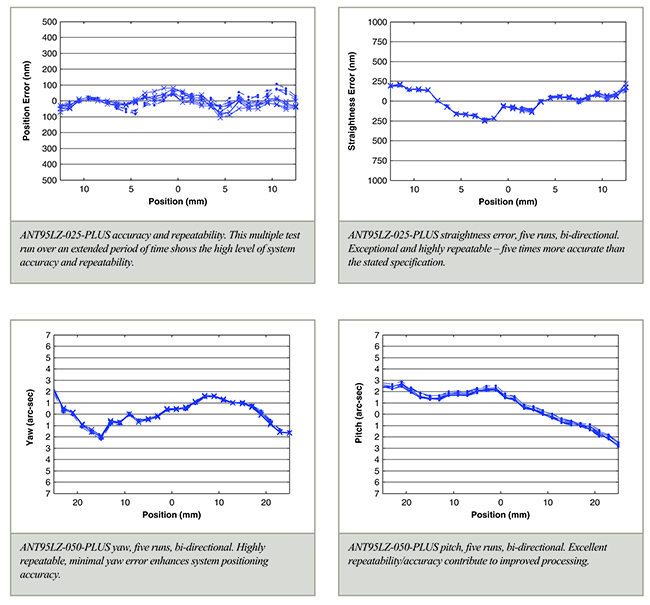

ANT95LZ Performance Graphs

Dimensions

ANT95LZ-025  Enlarge Image

Enlarge ImageANT95LZ-050  Enlarge Image

Enlarge Image

Ordering Information

ANT95LZ Single-Axis Z Direct-Drive Nanopositioning Stage

Travel (Required)

| Option | Description |

|---|---|

| -025 | 25 mm travel |

| -050 | 50 mm travel |

Cable Orientation (Required)

| Option | Description |

|---|---|

| -CBL1 | Right-hand cable exit |

| -CBL2 | Left-hand cable exit |

Performance Grade (Required)

| Option | Description |

|---|---|

| -PL1 | Base Performance |

| -PL2 | High-accuracy performance, PLUS |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

|---|---|

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |