Specifications

Mechanical Specifications

| Model | MPS75SLE-025 | MPS75SLE-050 | MPS75SLE-075 | MPS75SLE-100 | ||

|---|---|---|---|---|---|---|

| Travel | 25 mm | 50 mm | 75 mm | 100 mm | ||

| Accuracy | Uncalibrated | ±1.75 µm | ±2.25 µm | ±2.75 µm | ±3.25 µm | |

| Uncalibrated with Bellows | ±2.75 µm | ±3.25 µm | ±3.75 µm | ±4.25 µm | ||

| Calibrated(1) | ±0.75 µm | ±0.75 µm | ±1.0 µm | ±1.0 µm | ||

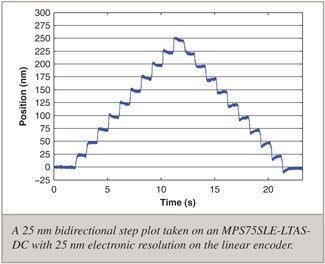

| Resolution (Minimum Incremental Motion)(2) | 0.025 µm | |||||

| Repeatability (Bidirectional)(2) | ±0.1 µm (Standard); ±0.2 µm (with Bellows) | |||||

| Straightness | ±2.0 µm | ±2.0 µm | ±3.0 µm | ±3.0 µm | ||

| Flatness | ±2.0 µm | ±2.0 µm | ±3.0 µm | ±3.0 µm | ||

| Maximum Speed | 1.0 mm/rev Ball Screw | DC Motor (-M1) | 50 mm/s | 50 mm/s | 50 mm/s | 35 mm/s |

| Stepper Motor (-M2) | 30 mm/s | 30 mm/s | 30 mm/s | 30 mm/s | ||

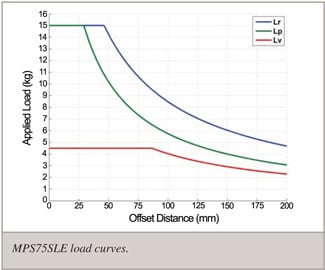

| Load Capacity(3) | Horizontal | 15 kg | ||||

| Side | 15 kg | |||||

| Vertical | 4 kg | |||||

| Stage Mass | 2.3 kg | 2.4 kg | 2.5 kg | 2.6 kg | ||

| Material | Anodized Aluminum Body | |||||

Available with Aerotech controllers.

Resolution and repeatability specifications are for systems running in dual-loop mode with feedback resolutions of 25 nm on both the rotary and linear encoders.

Payload specifications are single-axis.

Specifications are for single-axis systems measured 25 mm above the tabletop.

Contact factory for specifications of stages with bellows option.

Electrical Specifications

| Model | DC Motor | Stepper Motor |

|---|---|---|

| Drive System | DC Brush Servomotor | 24 VDC Bipolar Stepper Motor |

| Feedback (Linear Encoder) | Noncontact Linear Encoder; Amplified sine and TTL versions available | |

| Feedback (Rotary Motor Encoder) | 10,000 lines/rev Rotary Encoder | N/A |

| Maximum Bus Voltage | 48 VDC(1) | |

| Rotary Encoder Electronic Resolution | 0.025 µm | 0.025 µm @ 40,000 steps/rev Motor Resolution |

| Linear Encoder Electronic Resolution | 20 µm fundamental, 0.05 µm with LTX100 option; Amplified Sine (-AS) option allows for electronic resolutions below 1 nm(2) | |

| Limit Switches | 5V, Normally Closed | |

With Aerotech control system.

For optimum performance, Aerotech recommends using 0.025 µm as the highest-resolution when using the linear encoder as part of the servo feedback loop (e.g., dual-loop).

Recommended Controller

| Model | ||

|---|---|---|

| Multi-Axis | A3200 | Npaq/Npaq MR/Ndrive MP |

| Ensemble | Ensemble LAB/Epaq/Epaq MR/Ensemble MP | |

| Single Axis | Soloist | Soloist MP |

MPS75SLE Step Plot

MPS75SL Load Curves

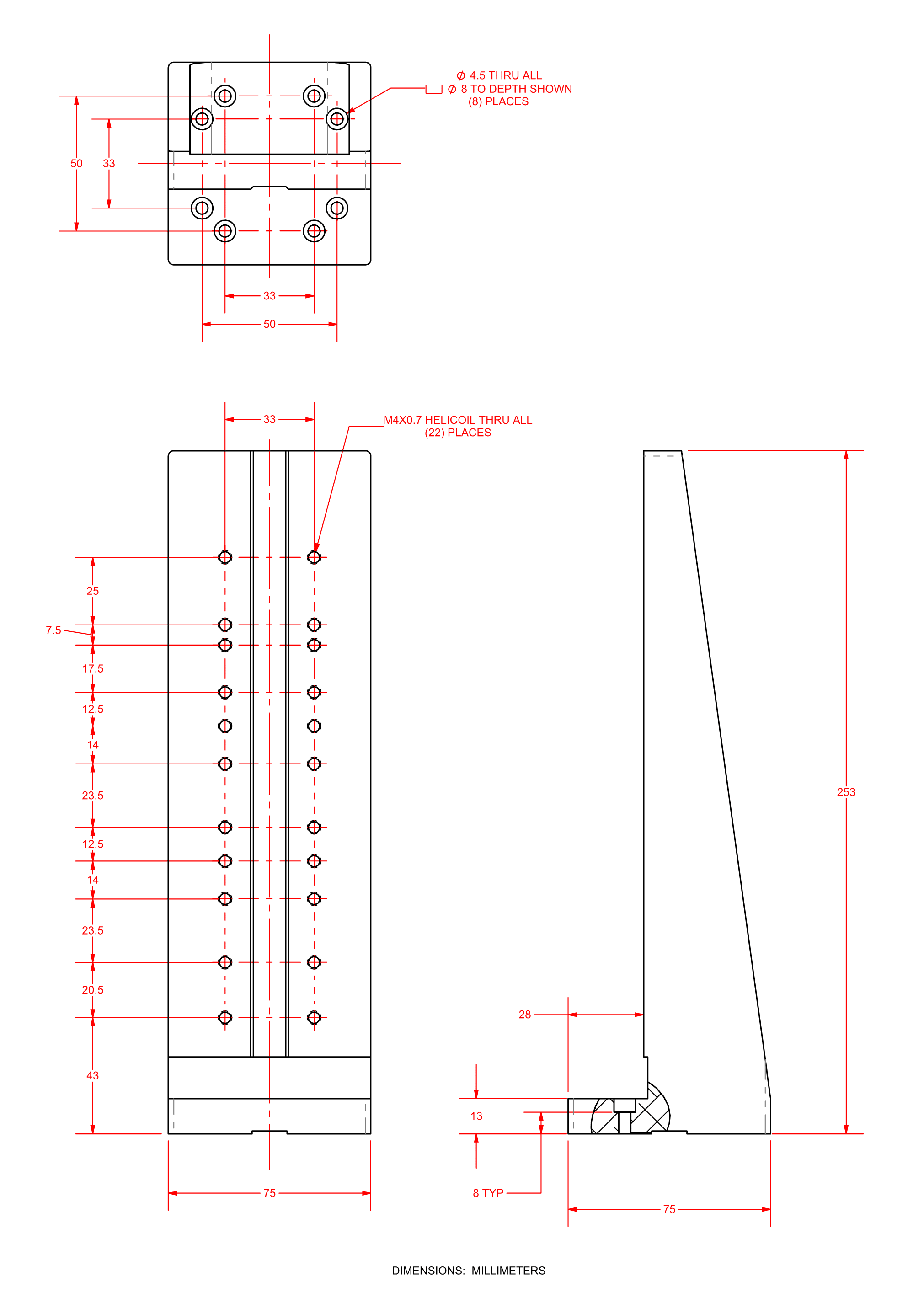

Dimensions

MPS75SLE  Enlarge Image

Enlarge ImageMPS75SLE Bellows Option  Enlarge Image

Enlarge ImageMPS75SLE Mounting Plates  Enlarge Image

Enlarge ImageHDZ-MPS75SLE L-Bracket  Enlarge Image

Enlarge Image

Ordering Information

MPS75SLE Miniature Mechanical-Bearing Screw-Driven Linear Stage with Linear Feedback

Direct Linear Feedback (Required)

| Option | Description |

|---|---|

| -E1 | Incremental linear encoder; 1 Vpp |

| -E2 | Incremental linear encoder; 0.05 µm digital TTL output |

Travel (Required)

| Option | Description |

|---|---|

| -025 | 25 mm travel stage |

| -050 | 50 mm travel stage |

| -075 | 75 mm travel stage |

| -100 | 100 mm travel stage |

Motor (Required)

| Option | Description |

|---|---|

| -M1 | DC servomotor |

| -M2 | Stepper motor |

Bellows (Optional)

| Option | Description |

|---|---|

| -BL | Bellows waycover |

Mounting Plate (Optional)

| Option | Description |

|---|---|

| -MP | Optical table mounting plate |

Metrology (Required)

| Option | Description |

|---|---|

| -PL0 | No metrology performance plots |

| -PL1 | Metrology, uncalibrated with performance plots |

| -PL2 | Metrology, calibrated (HALAR) with performance plots |

Integration (Required)

Aerotech offers both standard and custom integration services to help you get your system fully operational as quickly as possible. The following standard integration options are available for this system. Please consult Aerotech if you are unsure what level of integration is required, or if you desire custom integration support with your system.

| Option | Description |

|---|---|

| -TAS | Integration - Test as system Testing, integration, and documentation of a group of components as a complete system that will be used together (ex: drive, controller, and stage). This includes parameter file generation, system tuning, and documentation of the system configuration. |

| -TAC | Integration - Test as components Testing and integration of individual items as discrete components that ship together. This is typically used for spare parts, replacement parts, or items that will not be used together. These components may or may not be part of a larger system. |

Accessories (to be ordered as separate line item)

| Option | Description |

|---|---|

| HDZ-MPS75SL | Right angle bracket, MPS75SL |