Continuous 360 degree rotation of both axes

High axis positioning accuracy and repeatability

Low axis wobble and orthogonality

Direct-drive brushless servomotors

High accuracy induction feedback

Cog-free design for outstanding velocity stability

Accommodates loads up to 500 mm diameter

Vacuum-compatible versions available

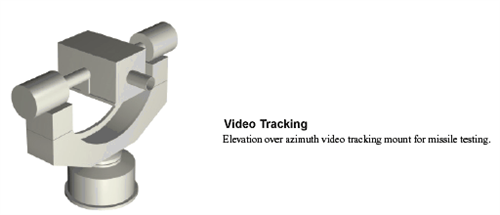

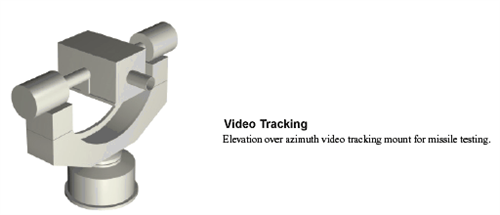

Aerotech\'s AOM360D series of positioning gimbal mounts provides ultra-precise elevation-over-azimuth positioning. The finest quality motors, bearings and transducers are incorporated into precision-machined housings to ensure peak performance.

The AOM360D series positioning gimbal mounts are ideal for automatic testing of components that must be precisely positioned in azimuth and elevation, such as sensors and optics. Other applications include calibration, laser beam steering, target acquisition and tracking, camera and telescope scanning and pointing.

Direct-drive brushless torque motors, incorporating rare-earth magnets and high-accuracy transducers, are coupled directly to precision shafts for accurate and smooth 360° continuous motion. The absence of gear trains and other drive mechanisms eliminates position error contributions due to mechanical hysteresis and backlash. Directly-coupled high-resolution inductosyn position transducers ensure highly accurate and repeatable positioning with gimbal accuracy down to ±5 µrad (±1 arc sec).

Large diameter, matched-set ABEC-7 bearings maximize performance with respect to wobble, moment stiffness and rotating friction. A thick-walled, precision-ground shaft further minimizes wobble. The large diameter bearing permits large payloads without compromising performance. Three tapped holes with leveling screws provide a convenient means to align the gimbal axes with the optical axis.

A variety of mirror cell diameters are available for standard optic applications. We also provide for custom payload attachment solutions to accommodate various device interfaces. Each gimbal mirror cell can be modified or replaced with different shaped cells to accommodate sensors or other odd shaped payloads. We understand customer payloads vary and our engineers have a variety of solutions to implement offset CG payloads.

To maximize positioning performance, AOM360D optical mounts utilize Aerotech’s S-series brushless, slotless servomotors. This motor has all of the advantages of a brushless direct-drive motor – no brushes to wear, no gear trains to maintain and high acceleration and high speeds. Since it is a slotless, ironless design, there is zero cogging, meaning that there is absolutely no torque ripple. This results in smoother motion throughout travel and more precise positioning.